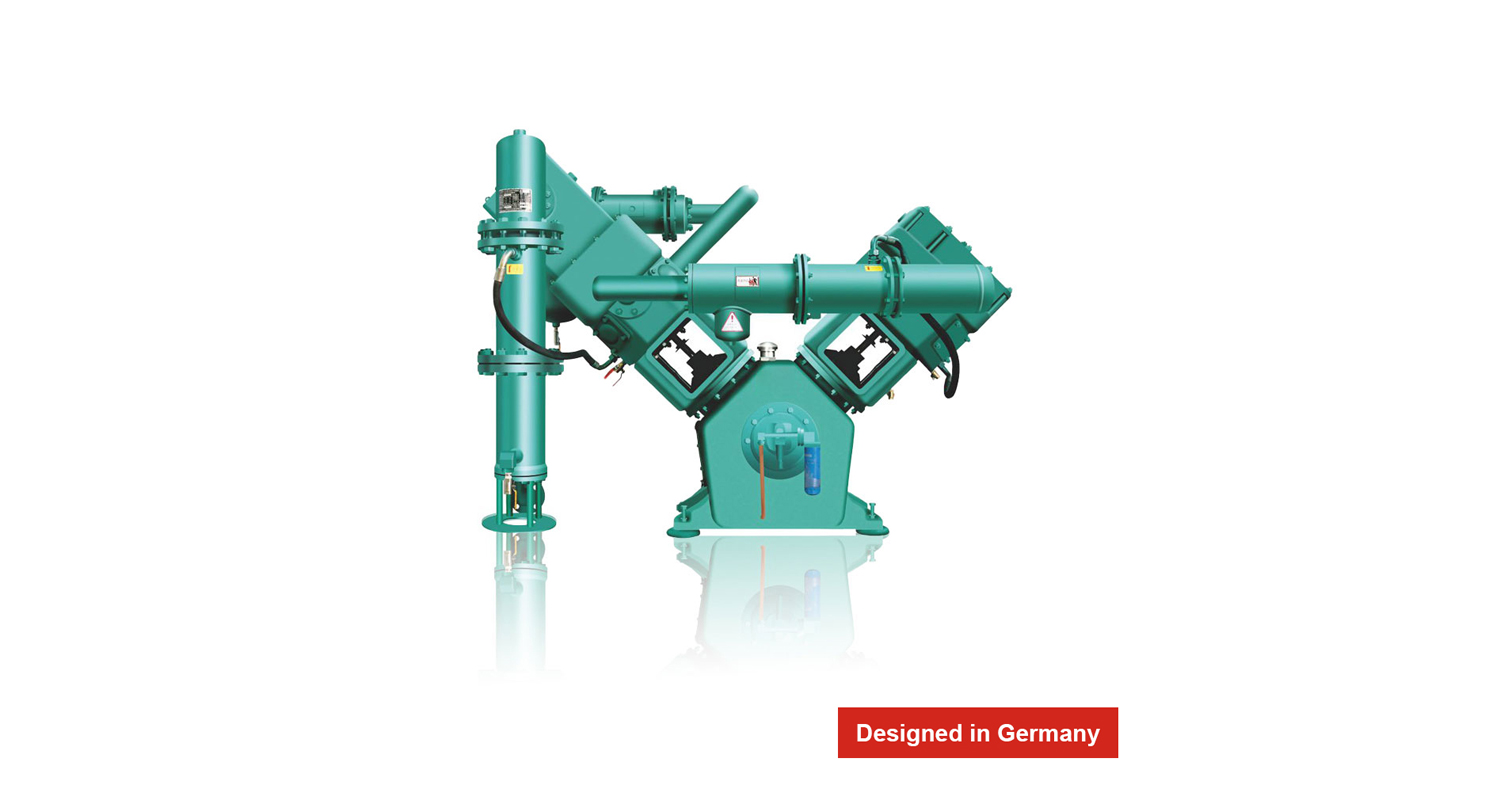

Nitrogen Industrial Piston Compressor

Motor Power: 22 – 125 kw

Discharged Pressure: 0.22 – 3 Mpa

Air Delivery: 3 – 10 m3/min

to become an agent. Learn more about agency policy.

More competitive agent price by FCL!

Nitrogen piston compressor is a product specially designed and developed for special gas media on the basis of our company’s leading product oil-free lubrication air compressor.

In addition to the characteristics of the air compressor, it has been specially designed for the particularity of the compressed medium. The model has a compact structure, small size, beautiful appearance, stable operation, low specific power, and low noise.

The main features are as follows:

1. Absolutely sealed, the compressed medium does not leak, ensuring environmental production safety.

2. Using oil-free lubrication, the compressed medium does not contain oil, does not react, and maintains the original gas characteristics.

3. Equipped with gas recovery device to avoid gas loss.

Application:

On-site:

| Nitrogen Piston Compressor Technical Parameter Table 1 | |||||||

| Model | EZW-10/10 | EZW-10/2.2 | EZW-10/7 | EZW-3/6 | EZW-3/8 | EZW-6/10 | |

| Type | Double cylinder double acting | Double cylinder single acting | Vertical double cylinder double acting | ||||

| Medium | Nitrogen | ||||||

| Stage | 2 | 1 | 2 | 2 | 2 | 2 | |

| Suction Pressure | MPa | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Discharged pressure | MPa | 1.0 | 0.22 | 0.7 | 0.6 | 0.8 | 1.0 |

| Capacity | m3/min | 10 | 10 | 10 | 3 | 3 | 6 |

| Speed | r/min | 740 | 740 | 740 | 730 | 730 | 740 |

| Shaft Power | kW | ≤66.7 | ≤30 | ≤58 | ≤18.5 | ≤12.3 | ≤40 |

| Cylinder dia | mm | φ285/φ170 | φ270+φ165 | φ285/φ175 | φ250/φ150 | φ250/φ150 | φ250/φ150 |

| Stroke | mm | 140 | 110 | 140 | 110 | 110 | 110 |

| Suction temp | ℃ | ≤40/45 | ≤40/45 | ≤40/45 | ≤35/45 | ≤35/45 | ≤40/45 |

| Discharged temp | ℃ | ≤160 | ≤160 | ≤160 | ≤160 | ≤160 | ≤160 |

| Temp.at outlet of cooler | ℃ | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 |

| Oil temp | ℃ | ≤70 | ≤70 | ≤70 | ≤70 | ≤70 | ≤70 |

| Cooling | Water cooling | ||||||

| Lubricating | Oil pump lubricates crankshaft, connecting rod, crosshead | ||||||

| Driving | Flexible coupling direct coupling | ||||||

| Max.temp.of intlet water | ℃ | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 |

| Max.temp.of outlet water | ℃ | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 |

| Cooling water consumption | m3/h | 2.4 | 2 | 2.4 | 1.5 | 1.5 | 2.4 |

| Motor Type | Y315M1-8 | Y280S-8 | Y280M2-8 | Y255M-8 | Y225M-8 | Y280M-8 | |

| Motor speed | r/min | 740 | 740 | 740 | 730 | 730 | 740 |

| Motor power | kW | 75 | 37 | 65 | 22 | 22 | 45 |

| Noise | dB(A) | ≤104 | ≤104 | ≤104 | ≤104 | ≤104 | ≤104 |

| Weight | kg | 2986 | 1500 | 2930 | 1600 | 1600 | 1600 |

| Dimensions (L×W×H) |

mm | 2250×1537×2100 | 2250×1545×2100 | 2250×1545×2075 | 2250×985×1800 | 2250×985×1800 | 2250×1545×2100 |

| Nitrogen Piston Compressor Technical Parameter Table 2 | |||||||

| Model | EZW-6/7 | EZW-6/7-I | EZW-7/8 | EVW-10/30 | EVW-6/30 | EVWWJ-8/25 | |

| Type | Double cylinder double acting | V-shaped, double-cylinder double-acting, differential | V-type, double-cylinder double-acting without foundation, step difference type | ||||

| Medium | Nitrogen | ||||||

| Stage | 2 | 2 | 2 | 3 | 3 | 3 | |

| Suction Pressure | MPa | 0.01~0.04 | 0.02~0.04 | 0.19 | 0.118 | ≤18KPa | 18KPa |

| Discharged pressure | MPa | 0.7 | 0.7 | 0.8 | 3.0 | 3.0 | 2.5 |

| Capacity | m3/min | 6 | 6 | 7 | 10 | 6 | 8 |

| Speed | r/min | 740 | 740 | 740 | 985 | 590 | 740 |

| Shaft Power | kW | ≤36 | ≤36 | ≤40 | ≤120 | ≤68 | ≤95 |

| Cylinder dia | mm | φ250/φ150 | φ250+φ150 | φ270/φ165 | φ320/φ240/φ125 | φ320/φ240/φ130 | |

| Stroke | mm | 110 | 110 | 110 | 104 | 104 | 104 |

| Suction temp | ℃ | ≤40/45 | ≤40/45 | ≤40/45 | ≤35/45/45 | ≤40 | |

| Discharged temp | ℃ | ≤160 | ≤160 | ≤160 | ≤180 | ≤180 | ≤160 |

| Temp.at outlet of cooler | ℃ | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 |

| Oil temp | ℃ | ≤70 | ≤70 | ≤70 | ≤70 | ≤70 | ≤70 |

| Cooling | Water cooling | ||||||

| Lubricating | Oil pump lubricates crankshaft, connecting rod, crosshead | ||||||

| Driving | Flexible coupling direct coupling | ||||||

| Max.temp.of intlet water | ℃ | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 |

| Max.temp.of outlet water | ℃ | ≤40 | ≤40 | ≤48 | ≤48 | ≤48 | ≤45 |

| Cooling water consumption | m3/h | 2 | 2 | 2.2 | 6 | 6 | 4.8 |

| Motor Type | Y280S-8 | Y280S-81P44 | Y280M2-8 | Y315M2-6B5 | Y315M2-10B5 | Y315M2-8B5 | |

| Motor speed | r/min | 740 | 740 | 740 | 985 | 590 | 590 |

| Motor power | kW | 37 | 37 | 45 | 125 | 75 | 95 |

| Noise | dB(A) | ≤104 | ≤104 | ≤104 | ≤105 | ≤105 | ≤105 |

| Weight | kg | 1435 | 1435 | 1450 | 4400 | 4400 | |

| Dimensions(L×W×H) | mm | 2250×1546×1833 | 2250×2050×2180 | 2443×2300×1780 | 2443×2300×1890 | ||

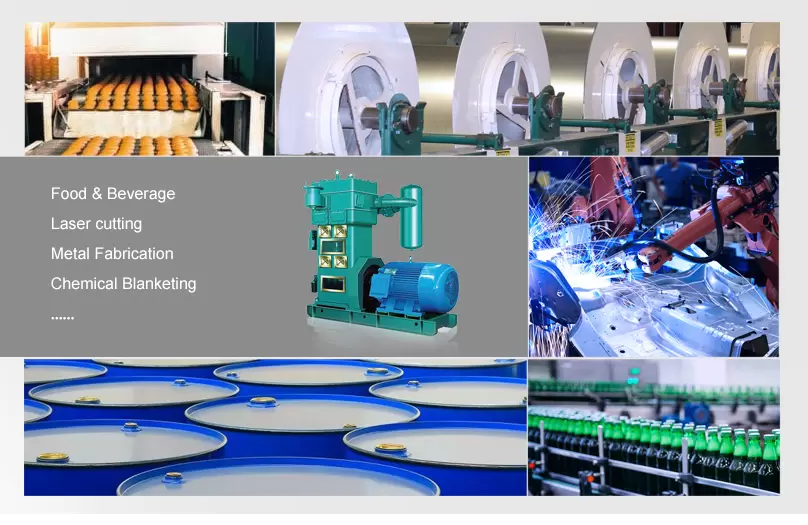

Application

Nitrogen is widely used in chemical, electronic, metallurgy, food, machinery and other fields.

In the semiconductor industry, nitrogen is extensively used as a purge and carrier gas. In the field of electronic products, nitrogen is used as an inert in epitaxial growth furnaces. It can also be used as carrier gas, zero-grade calibration gas and balance gas in laboratory analysis. Other common applications include heat treatment, ammonia production, fire suppression in mines, tire inflation, shrink fit and cooling, where nitrogen can help improve vacuum efficiency.

Industrial Production of Nitrogen Gas

The industrial production of nitrogen gas derives its raw materials from the air and utilizes methods such as cryogenic air separation (deep cold air separation for nitrogen), membrane separation, and adsorption processes (Pressure Swing Adsorption method, PSA). The collection, separation, transportation, and filling processes all require compression technology.

Why oxygen compressors need to be oil-free?

While nitrogen gas is an inert gas and does not react with oil, many people believe that it doesn’t matter if there is oil in the process of compressing nitrogen gas. Is this really the case?

First, nitrogen gas, especially high-purity nitrogen gas (with a purity of 99.9% or higher), is prohibited from containing oil in application fields such as electronics, food, pharmaceutical production, and more. If oil-contaminated nitrogen gas is treated to become oil-free through technical processes, there is a significant risk. It is better to use physically oil-free compressors – oil-free lubrication nitrogen compressors.

Second, all high-pressure gases are prohibited from containing oil. Therefore, in applications involving high-pressure nitrogen gas, it is essential to use oil-free lubrication nitrogen compressors.

So, it is essential that the compressor is oil-free during nitrogen compression.