Quick Link

Elang offers a wide range of reliable oil-free air compressors in a variety of different types to meet the needs of a wide range of industries and applications. We will evaluate and advise you on the most suitable oil-free solution to improve the production efficiency of your equipment and ensure that the product is at zero risk of contamination. This helps protect your brand reputation and enhances the credibility of your products in the market.

Four Advantages of Oil Free Air Compressor

Reliable product and system design can provide high-quality air, protect sensitive downstream gas equipment, reduce maintenance and extend equipment life.

Utilizing Class 0 certified oil free compressors ensures contamination-free air, eliminating the risks of product damage and wastage.

Our oil-free compressor is specifically designed for ease of maintenance, allowing convenient access to consumable spare parts.

The initial cost of an oil-free system is relatively high, but its operating and maintenance costs throughout its entire lifecycle are relatively low, which can be offset while maintaining higher air quality.

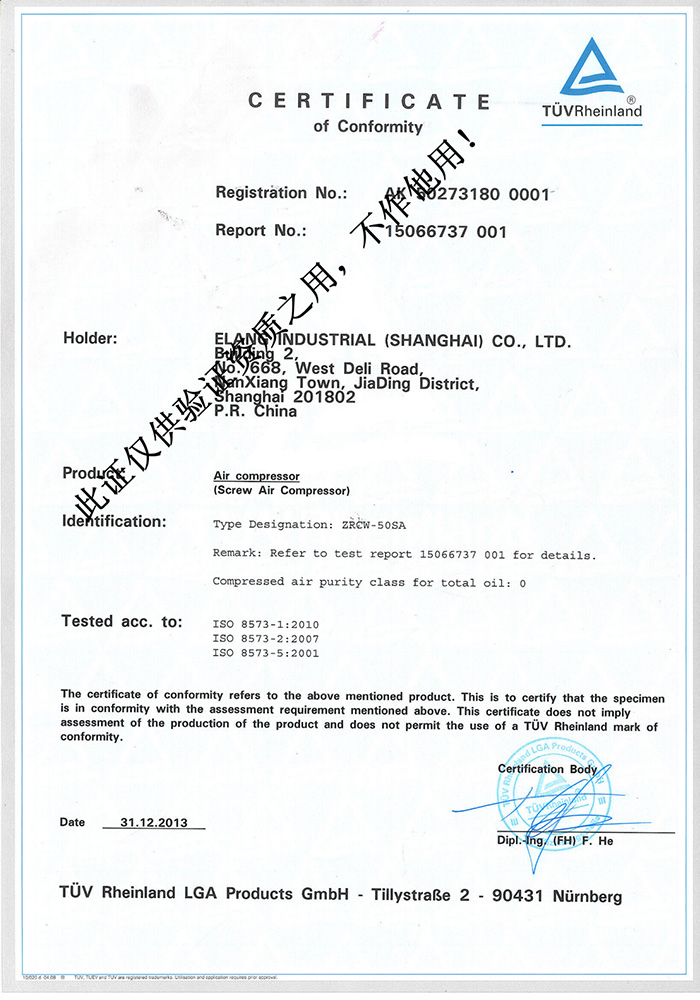

Class 0 ISO 8573-1 for Oil-free Air

| ISO 8573-1 Air Quality Level | |

| Air Quality Level | oil, and oil vapor (mg/m3) |

| 0 | <0.01 |

| 1 | 0.01 |

| 2 | 0.1 |

| 3 | 1 |

| 4 | 5 |

Oil-free Zero Class is the most demanding air class defined by ISO 8573 Part 1. The entire range of Elang oil-free air compressors has passed TUV oil-free certification

- Smaller FootprintThe compact design and small footprint save users more space

- Fewer Spare PartsHigher reliability, longer life and less maintenance

- Lower Noise LevelA healthier work environment

- 100% Oil Free Can be used in any industry

- Fewer Wearing PartsLonger maintenance intervals and service life

- No Metal FrictionLess maintenance

- Zero EmissionsConsistent with sustainable development goals

- Insufficient Sports Spare PartsLess vibration

Clean Air | Low Noise | High Effiency

Working Pressure: 6 – 8 bar

Air Delivery: 0.24 – 0.6 m3/min

| Smaller Footprint |

|

The compact design and small footprint save users more space |

| Fewer Spare Parts |

|

Higher reliability, longer life and less maintenance |

| Lower Noise Level |

|

A healthier work environment |

| 100% Oil Free |

|

Can be used in any industry |

| Fewer Wearing Parts |

|

Longer maintenance intervals and service life |

| No Metal Friction |

|

Less maintenance |

| Zero Emissions |

|

Consistent with sustainable development goals |

| Insufficient Sports Spare Parts |

|

Less vibration |

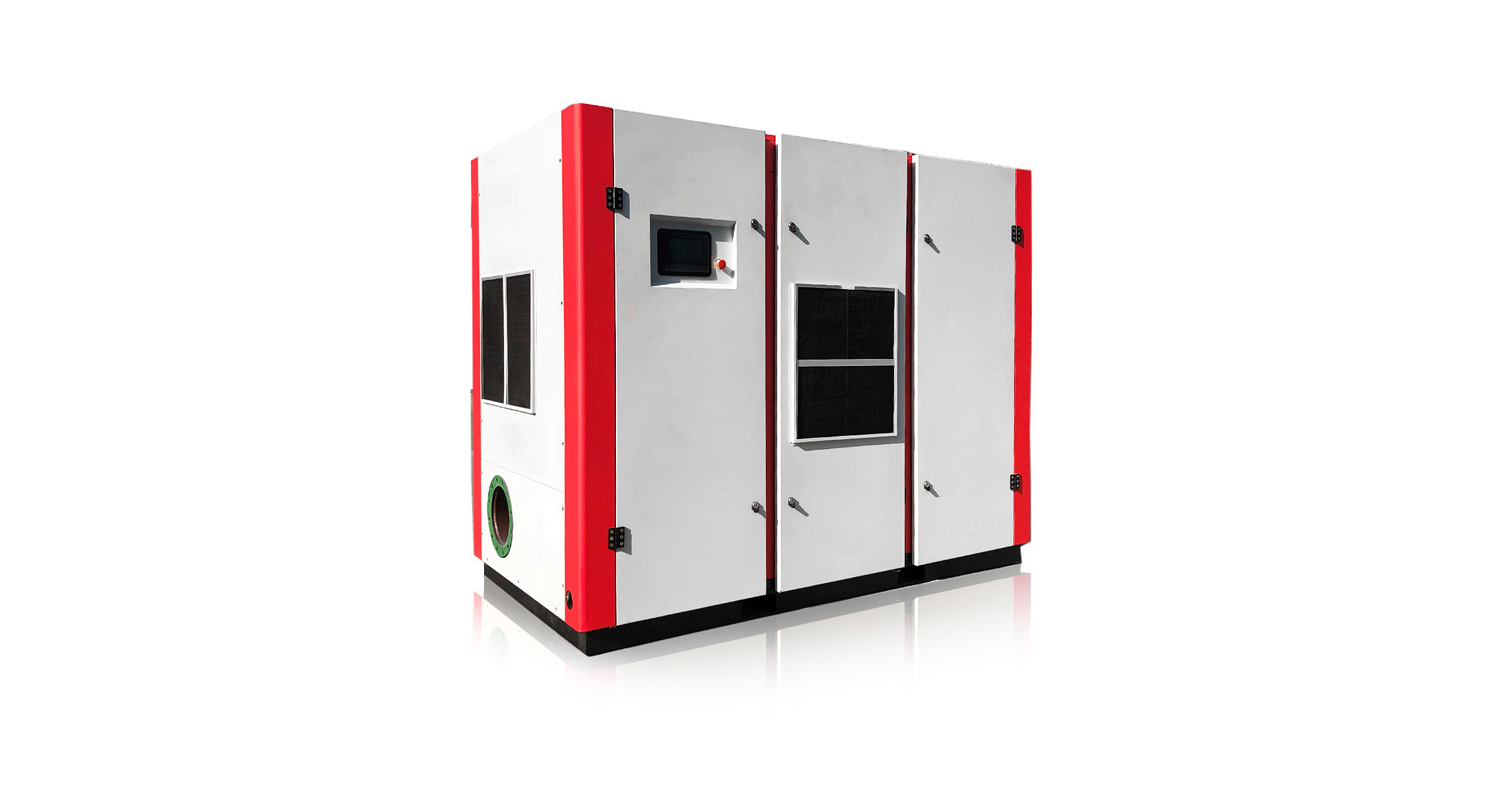

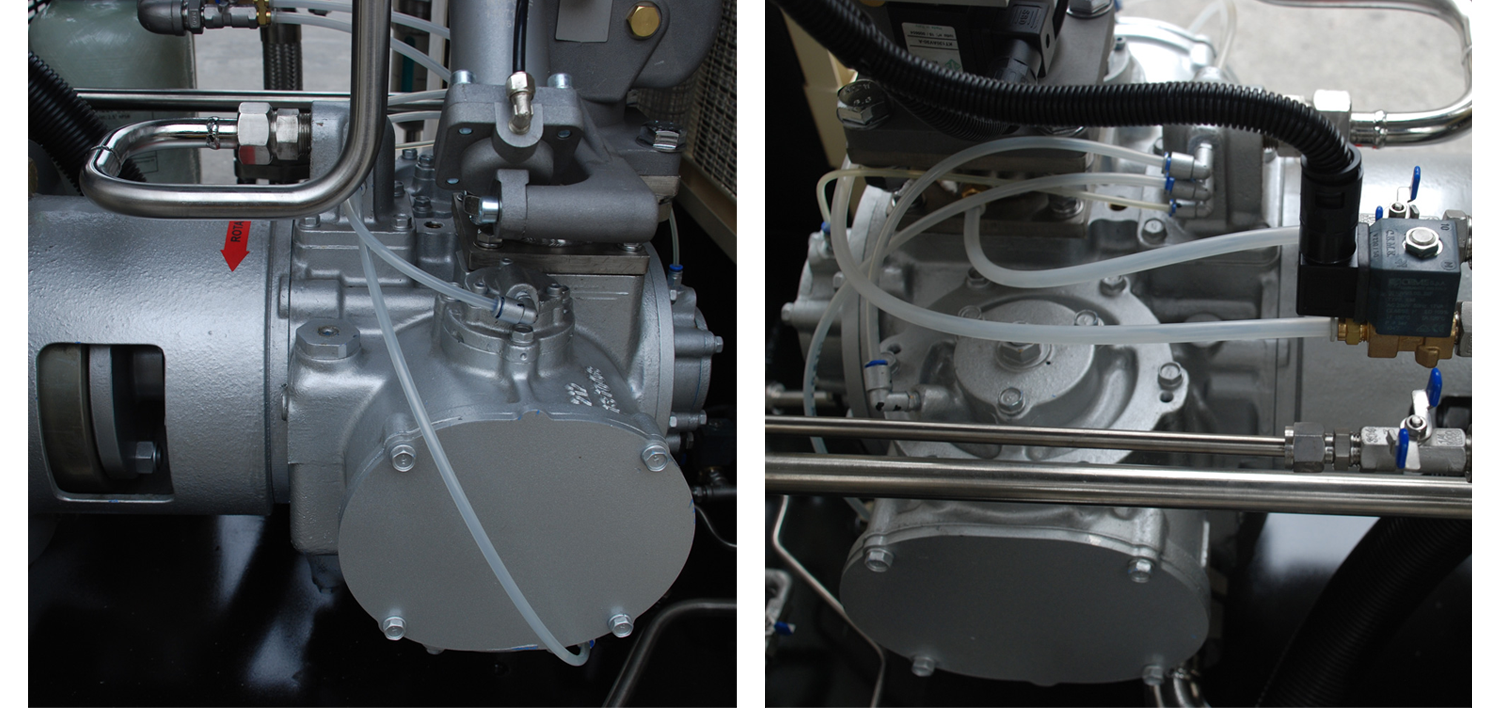

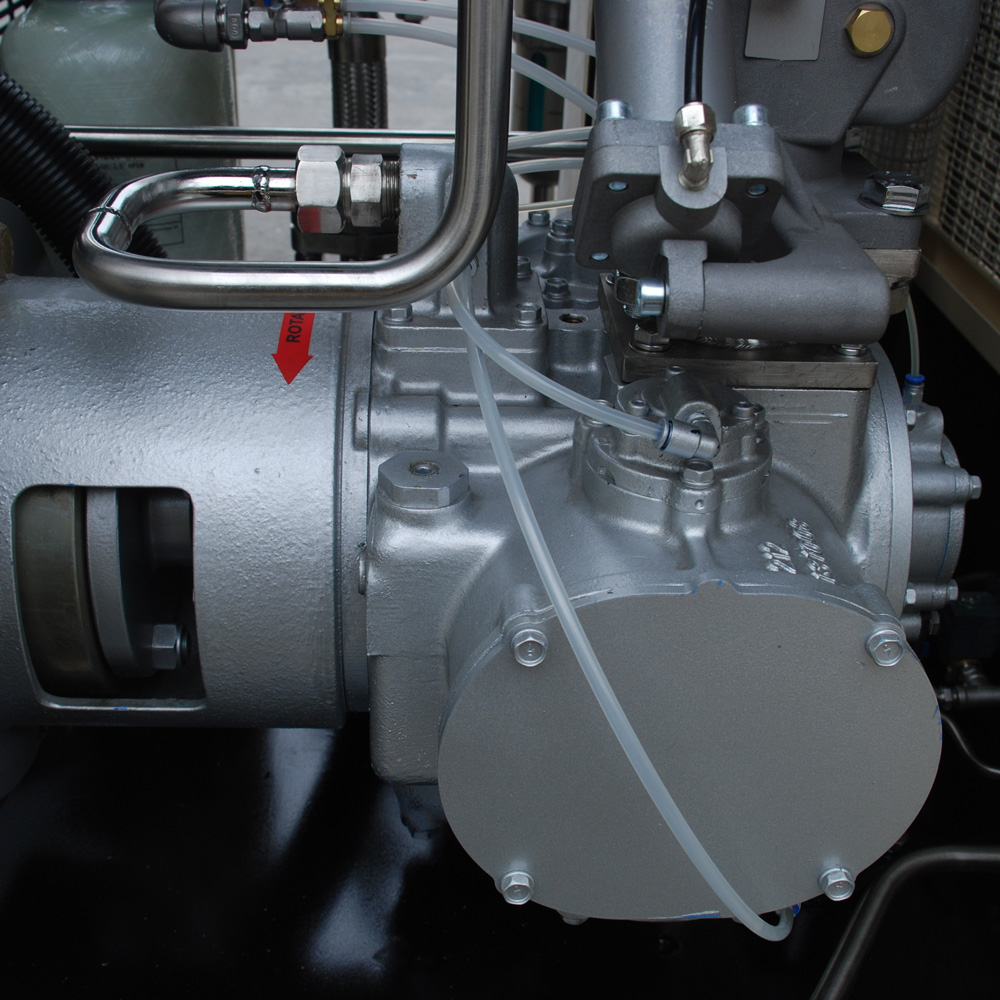

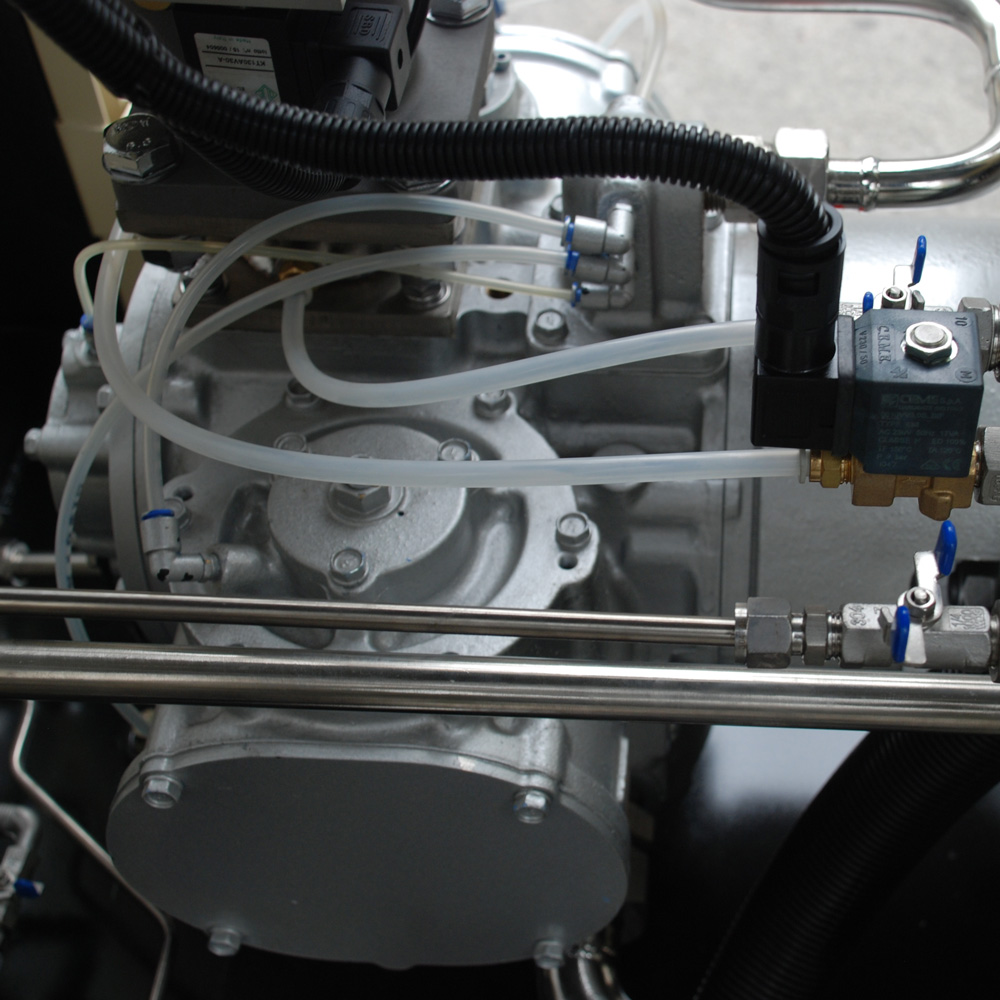

Elang oil-free vsd air compressor adopts water lubrication cooling technology, and the compression chamber does not use oil coolant, providing users with pure compressed air to meet various production needs.

100% Oil Free |

Reliability |

Energy Saving |

Low Noise |

- High Reliability, 24 hours running

- Purchase cost and maintenance cost make up only 20% of the total, while energy consumption accounts for 80%. Elang VSD compressors save over 30% energy compared to fixed speed compressors.

- PLC control, remote operation, multi-machine control supplied

- The rotor of oil free air end is made of stainless steel material, which will never rust.

- Adopting stainless steel bearings to ensure the reliability of water lubrication, high efficiency, and low noise.

- Independently developed, multiple patent certificates, 5-year warranty for air end.

Working Pressure: 7 – 12.5 bar

Air Delivery: 2.3 – 43 m3/min

100% Oil Free |

Reliability |

Energy Saving |

Low Noise |

- The rotor of oil free air end is made of stainless steel material, which will never rust.

- Adopting stainless steel bearings to ensure the reliability of water lubrication, high efficiency, and low noise.

- Independently developed, multiple patent certificates, 5-year warranty for air end.

- Long Service Life

The air end uses special coating materials and processes to make it resistant to high temperatures and high pressures, extending the service life of the air end.

- Low Noise

The unique labyrinthine intake, impedance release silencing system, and fully enclosed multiple soundproof / absorption door panels ensure a perfect noise shielding effect.

- Stable Operation

The cooling system adopts stainless steel fin tubes and aluminum plate-fin heat exchanger in series for cooling, with high cooling efficiency and ensuring stability in high-temperature environments.

- Wide Frequency Range

Equipped with a permanent magnet motor, high efficiency and a wide frequency conversion range.

- Class 0 Oil Free

Provide pure compressed air that meets IS08573-1:2010 Class 0 certification, and is suitable for a wide range of applications in the fields of pharmaceuticals, healthcare, food processing, chemicals, electronics, and instrumentation.

Working Pressure: 5 – 10 bar

Air Delivery: 7.8 – 72 m3/min

Elang medium pressure water lubricated air compressor is mainly used in PET bottle blowing. Compared with piston air compressor, it has 4 outstanding advantages.

| 16 – 40 bar Water Lubricated Screw Air Compressor | 16 – 40 bar Piston Air Compressor | |

| Air Quality | Pure Oil Free | Unable to Achieve truly Oil-free |

| Noise Level | 70 – 80 dB(A) | Above 100 dB(A) |

| Maintenance Time | 1-2 hours / time | 2-3 days / time |

| Maintenance Cost | Few Maintenance Parts and Low Cost | Many Maintenance Parts and High Cost |

Working Pressure: 16 – 40 bar

Air Delivery: 1.9 – 43.1 m3/min

Both screw blower and roots blower is positive displacement fan. If the two are compared, the screw blower is more energy saving, stability and low noise.

In fact, the higher pressure of usage, the more energy saving the screw blower is compared with the Roots blower.

At the pressure of 0.5bar, compared with roots blower, screw blower save more than 35% energy.

| Screw Blowers | End User requirements | Roots Blowers |

| Motor Power: 37 kw Air Flow:25.5m3/min Full load of 8000 hours a year, power consumption 296000 Degrees |

Working Pressure: 0.7 bar Air Flow:23.8 m3/min |

Motor Power: 55kw Air Flow:24.04m3/min Full load of 8000 hours a year, power consumption 440000 Degrees |

| One year: screw blower can save power 144000 degrees | ||

Working Pressure: 40 – 150 Kpa

Air Delivery: 4 – 100.7 m3/min

Elang centrifugal air compressor has the advantages of high efficiency, wide air flow and pressure range, and low maintenance costs. It can be widely used in thermal power plants, petrochemical, chemical, sewage treatment plants and other industries.

The equipment can be configured with a waste heat recovery device, which has high recovery efficiency and the outlet water temperature range is 50 – 90 ℃.

Working Pressure: 1.2 – 30 Bar

Air Delivery: 55 – 2000 m3/min