ELANG Co., Ltd. participated in the 2024 International Machinery Exhibition held in Uzbekistan from June 12 to June 14. Our company’s exhibition booth is at No. 22, Zone C. This grand exhibition attracted exhibitors from industries such as fluid transmission, compressed air and vacuum, internal logistics and supply chain, heavy machinery, industrial subcontracting, and lightweight construction, […]

Printing industry – a paper printing factory Application link: adsorption and grabbing of paper Equipment type: EOV series oil-injected screw vacuum pump complete machine Industry introduction: The centralized system of the printing industry basically adopts a three-pipe control system, which usually consists of vacuum system, a micro-positive pressure system and a conventional compressed air system, which […]

As we all know, to improve the processing efficiency of a laser cutting machine, it is necessary to introduce auxiliary gases during the processing, such as air, oxygen, nitrogen, and other gases. Among these auxiliary gases, air is the most cost-effective option and is preferred by most customers. Therefore, to improve cutting performance, it is essential to have a special air compressors for laser cutting machine.

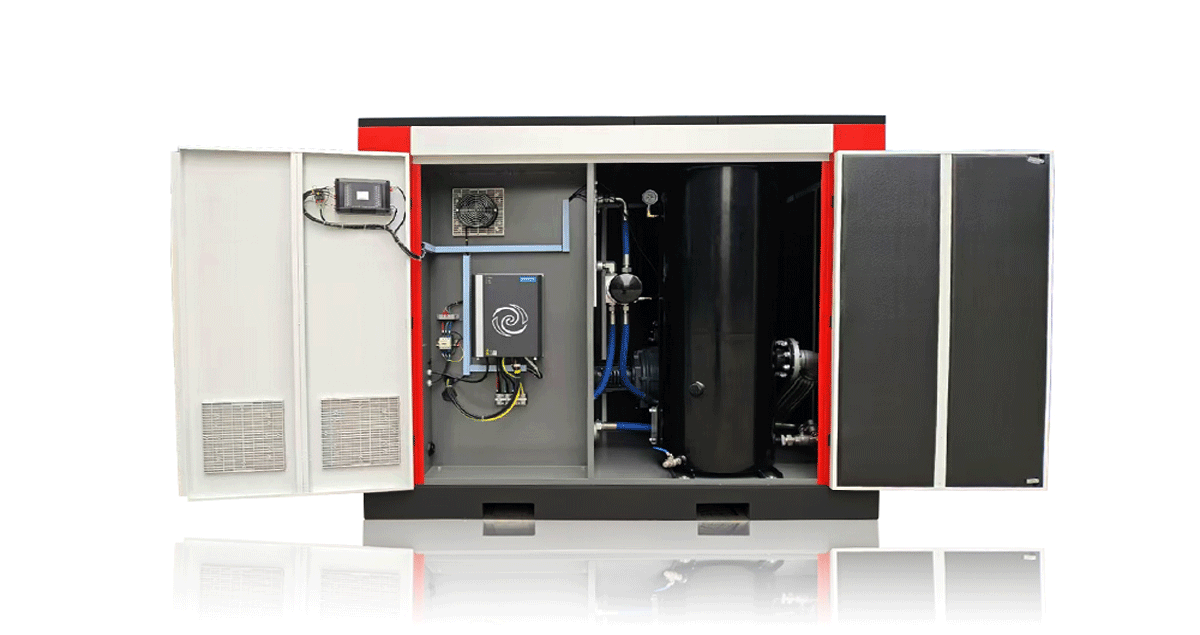

As an economical air compressor, this article focuses on introducing the supply air principle and the main features of twin-screw air compressors, including easy maintenance, low failure rate, and high level of automation.

The petroleum industry is a major user of energy production and energy consumption. Air compressors are widely used in the petroleum & chemical industry to reduce energy consumption costs and improve production efficiency.

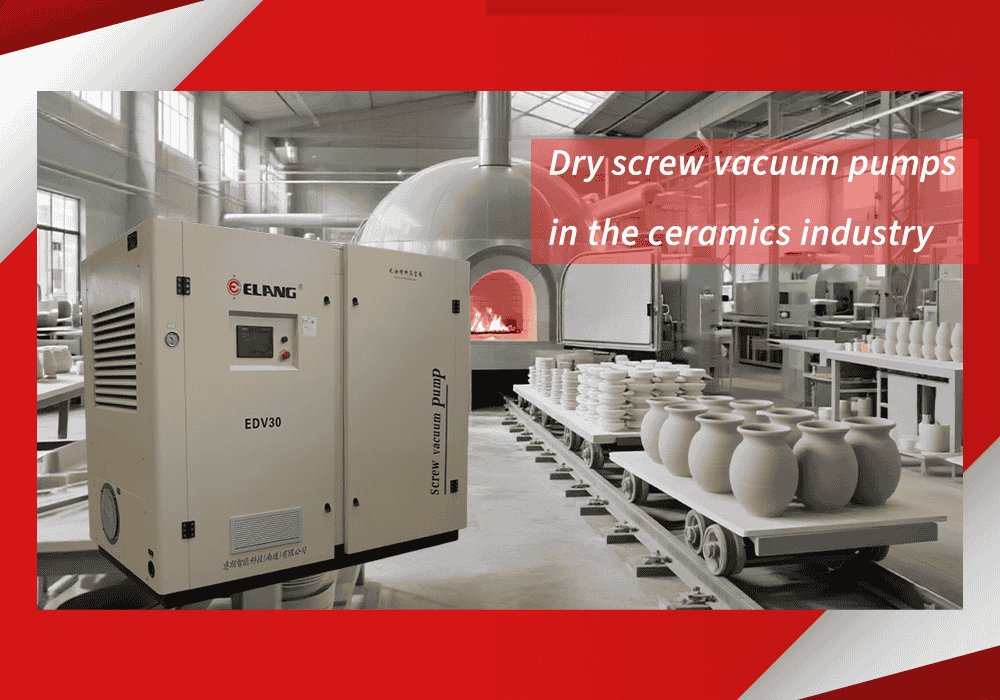

Through this article, you will see how Elang helps ceramic industry customers achieve energy saving and consumption reduction through a vacuum system transformation.

Discover how sensors transform screw compressors from blind operators to intelligent systems. Temperature, pressure, vibration, and other sensors act as the machine's "eyes and ears," enabling real-time monitoring, predictive maintenance, and 30%+ energy savings. This article reveals why these unassuming components are critical for reliability, cost reduction, and seamless industrial operations.

As an expert in compressed air systems for over 20 years, Elang provides you with complete solutions that are reliable and energy-efficient.

How to convert psi to bar? For all other types of unit conversions for air compressors, we offer a free and easy to use online tool that explains the standards and details.