In the realm of glass manufacturing, compressors play a pivotal role in ensuring the efficient and seamless production of this versatile material. Compressors drive pneumatic machinery, facilitating the transfer of raw materials, maintaining optimal temperatures, and enabling the formation and cutting processes.

Although compressors in glass factories are often located in a fixed room or corner, the compressed air they produce is used throughout almost the entire glass production line.

How are raw materials transported? Air compressors help

The first step in glassmaking is transporting sand. Air compressors provide compressed air to the starting equipment, which, of course, drives the equipment to transport the sand. The goal is simple: everything is automated. Crucially, this simple design not only saves labor but also ensures a constant supply of raw materials, preventing production delays.

A role in melting and mixing

After the raw materials arrive at the factory, they undergo high-temperature melting and mixing. Air compressors drive conveyor belts that move the raw materials between tanks. Compressed air ensures a smooth and orderly process, ensuring a more even mixing of the raw materials.

Rapid Cooling and Forming

Simply put, it blows cold air onto the hot, melted and mixed glass to cool it down and quickly set its shape. This results in faster production and a harder glass.

A role in the cutting process

After the glass has hardened, it is cut. Air compressors power cutting tools, ensuring precise and clean cuts, whether small or large.

It’s fair to say that without an air compressor, the entire glass production process would slow down or even come to a halt.

Glass manufacturing industry chooses compressor

When choosing a compressor for the glass industry, consider the following points.

Oil-Immersed vs. Oil-Free

Although oil-immersed screw air compressors offer a low initial investment and a wide range of airflow, the compressed air they produce contains oil. To prevent oil in the compressed air from contaminating glass or damaging other equipment, a high-efficiency oil removal filter, such as an activated carbon filter, is essential. Frequent replacement of oil filters and lubricants also incurs significant costs.

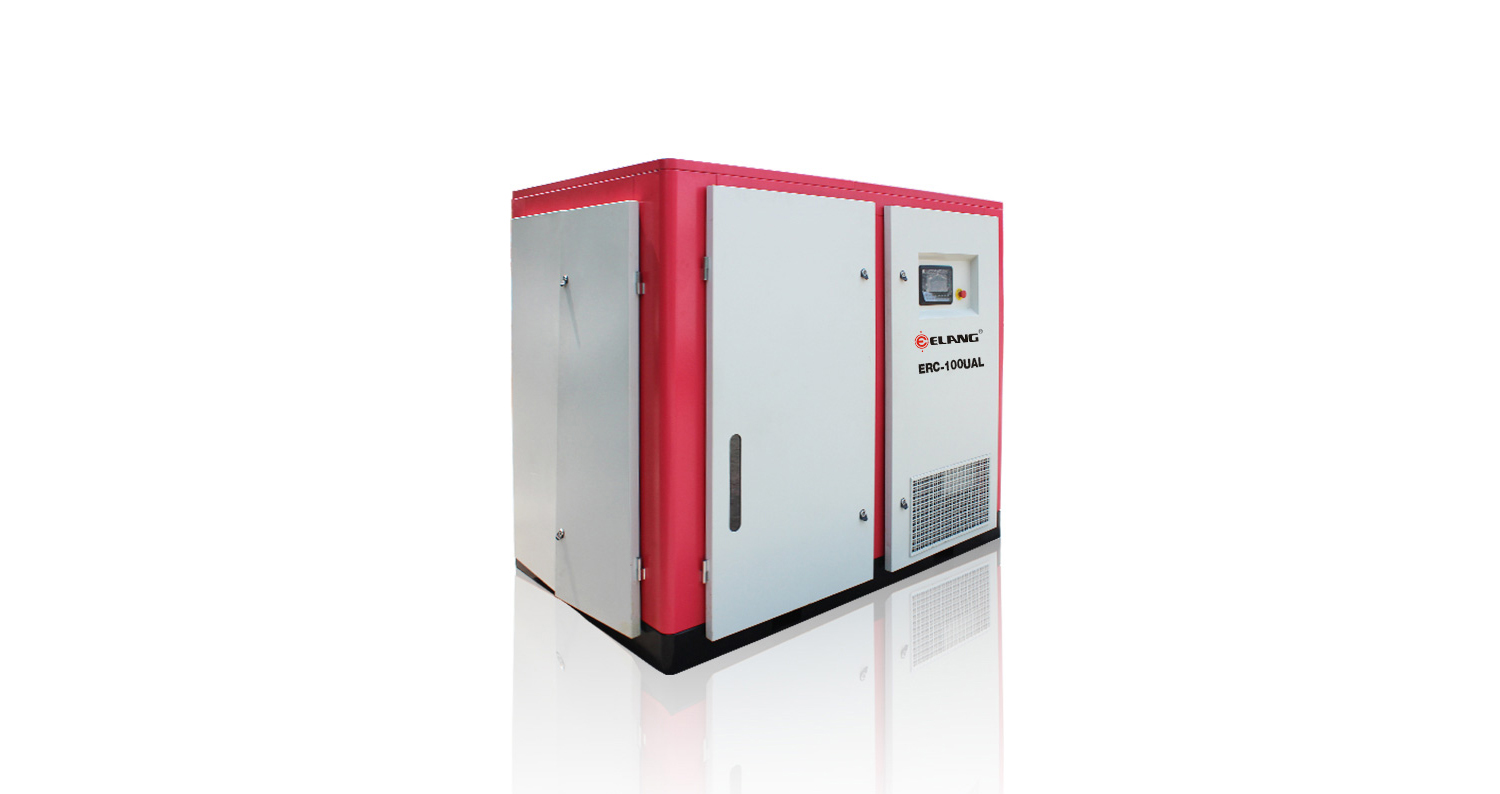

Oil-free screw air compressors or centrifugal air compressors naturally eliminate the aforementioned concerns about oil in the compressed air, providing 100% oil-free compressed air from the source. They are currently the preferred choice for electronic and medical glass applications. However, these alternatives come with a higher price tag and require more technical expertise for installation and maintenance. Therefore, choosing a trustworthy brand and reliable after-sales service is crucial. For example, Elang has been immersed in the compressor industry for many years, offering comprehensive R&D, sales, and after-sales service compared to other brands.

Flow and Pressure

Flow is the key parameter and should be determined based on the combined air consumption of all pneumatic equipment. A 10% to 20% margin should also be added. In the glass industry, a standard pressure of 6 to 8 bar (0.6 to 0.8 MPa) is commonly used.