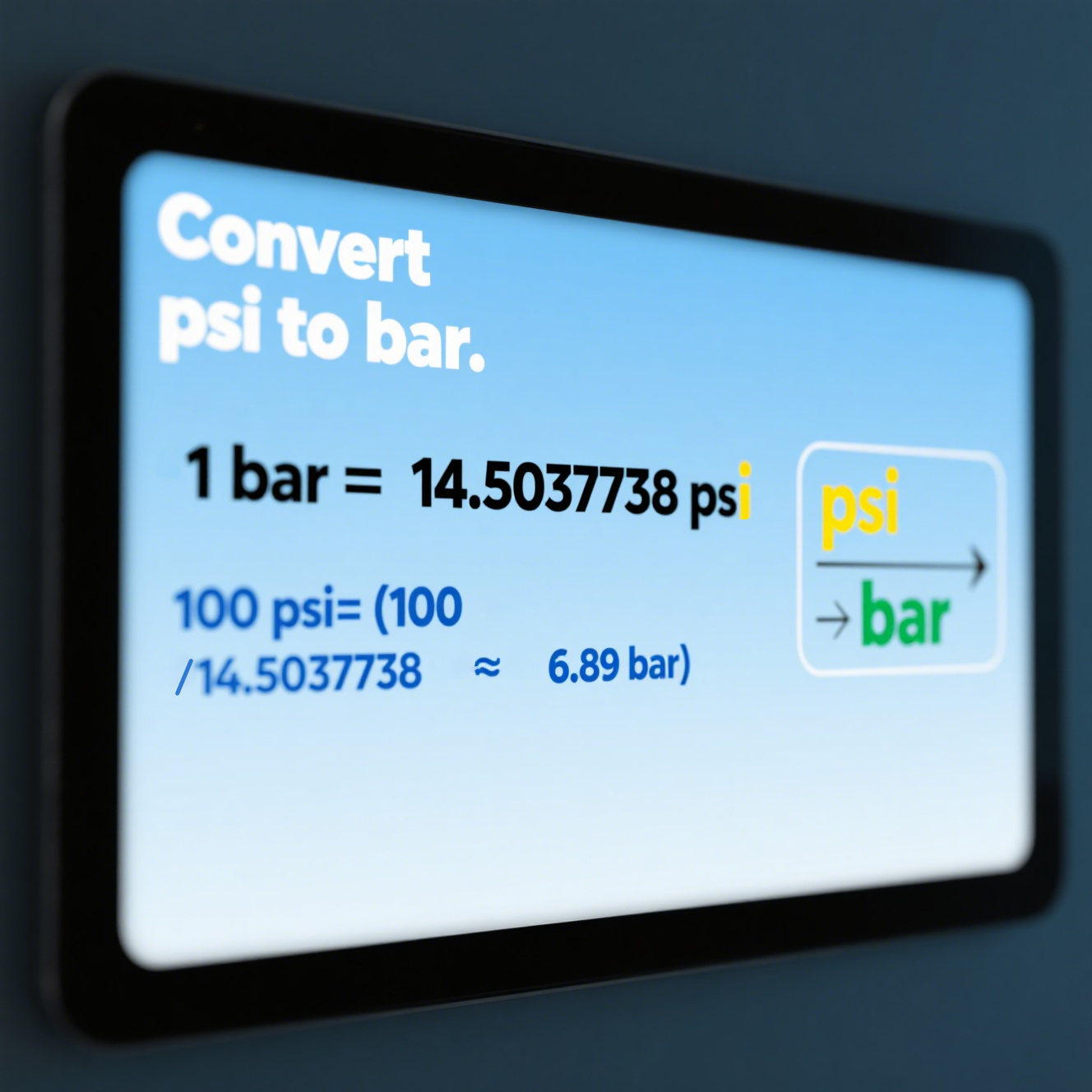

How to convert psi to bar? For all other types of unit conversions for air compressors, we offer a free and easy to use online tool that explains the standards and details.

Convert psi to bar tool

Pressure

PSI ↔ Bar

Power

kW ↔ HP

Flow Rate

m³/min ↔ CFM

Convert Bar to Psi Table

| Common conversions | Conversion results |

|---|---|

| 0.1 bar to psi | 0.1 bar = 1.4504 psi |

| 0.14 bar to psi | 0.14 bar = 2.0305 psi |

| 0.15 bar to psi | 0.15 bar = 2.1756 psi |

| 0.2 bar in psi | 0.2 bar = 2.9008 psi |

| 0.25 bar to psi | 0.25 bar = 3.6260 psi |

| 0.3 bar to psi | 0.3 bar = 4.3511 psi |

| 0.35 bar to psi | 0.35 bar = 5.0763 psi |

| 0.4 bar to psi | 0.4 bar = 5.8015 psi |

| 0.45 bar to psi | 0.45 bar = 6.5267 psi |

| 0.5 bar in psi | 0.5 bar = 7.2519 psi |

| 0.6 bar to psi | 0.6 bar = 8.7023 psi |

| 0.7 bar to psi | 0.7 bar = 10.1527 psi |

| 0.75 bar to psi | 0.75 bar = 10.8779 psi |

| 0.8 bar to psi | 0.8 bar = 11.6030 psi |

| 0.9 bar in psi | 0.9 bar = 13.0534 psi |

| 1 bar to psi | 1 bar = 14.5038 psi |

| 1.1 bar to psi | 1.1 bar = 15.9542 psi |

| 1.2 bar to psi | 1.2 bar = 17.4046 psi |

| 1.3 bar to psi | 1.3 bar = 18.8549 psi |

| 1.4 bar to psi | 1.4 bar = 20.3053 psi |

| 1.5 bar to psi | 1.5 bar = 21.7557 psi |

| 1.6 bar to psi | 1.6 bar = 23.2061 psi |

| 1.7 bar to psi | 1.7 bar = 24.6565 psi |

| 1.8 bar to psi | 1.8 bar = 26.1068 psi |

| 1.9 bar to psi | 1.9 bar = 27.5572 psi |

| 2.0 bar to psi | 2 bar = 29.0076 psi |

| 2.1 bar to psi | 2.1 bar = 30.4580 psi |

| 2.2 bar to psi | 2.2 bar = 31.9084 psi |

| 2.3 bar to psi | 2.3 bar = 33.3587 psi |

| 2.4 bar to psi | 2.4 bar = 34.8091 psi |

| 2.5 bar to psi | 2.5 bar = 36.2595 psi |

| 2.6 bar to psi | 2.6 bar = 37.7099 psi |

| 2.7 bar to psi | 2.7 bar = 39.1603 psi |

| 2.8 bar to psi | 2.8 bar = 40.6106 psi |

| 2.9 bar to psi | 2.9 bar = 42.0610 psi |

| 3 bar to psi | 3 bar = 43.5114 psi |

| 4 bar to psi | 4 bar = 58.0152 psi |

| 5 psi to bar | 5 psi = 0.3447 bar |

| 5.5 bar in psi | 5.5 bar = 79.7709 psi |

| 6 bar to psi | 6 bar = 87.0228 psi |

| 7 bar to psi | 7 bar = 101.5266 psi |

| 8 bar to psi | 8 bar = 116.0304 psi |

| 9 bar to psi | 9 bar = 130.5342 psi |

| 10 bar to psi | 10 bar = 145.0380 psi |

| 15 bar to psi | 15 bar = 217.5570 psi |

| 20 bar to psi | 20 bar = 290.0760 psi |

| 25 bar to psi | 25 bar = 362.5950 psi |

| 30 bar to psi | 30 bar = 435.1140 psi |

| 35 bar to psi | 35 bar = 507.6330 psi |

| 40 bar to psi | 40 bar = 580.1520 psi |

| 45 bar to psi | 45 bar = 652.6710 psi |

| 50 bar to psi | 50 bar = 725.1900 psi |

| 55 bar to psi | 55 bar = 797.7090 psi |

| 60 bar to psi | 60 bar = 870.2280 psi |

| 70 bar to psi | 70 bar = 1015.2660 psi |

| 80 bar to psi | 80 bar = 1160.3040 psi |

| 90 bar to psi | 90 bar = 1305.3420 psi |

| 100 bar to psi | 100 bar = 1450.3800 psi |

| 200 bar to psi | 200 bar = 2900.7600 psi |

| 300 bar to psi | 300 bar = 4351.1400 psi |

| 400 bar to psi | 400 bar = 5801.5200 psi |

| 500 bar to psi | 500 bar = 7251.9000 psi |

| 600 bar to psi | 600 bar = 8702.2800 psi |

| 700 bar to psi | 700 bar = 10152.6600 psi |

| 800 bar to psi | 800 bar = 11603.0400 psi |

| 900 bar to psi | 900 bar = 13053.4200 psi |

| 1000 bar to psi | 1000 bar = 14503.8000 psi |

Convert Psi to Bar Table

| Common conversions | Conversion results |

|---|---|

| 10 psi to bar | 0.6895 bar |

| 20 psi to bar | 1.3790 bar |

| 30 psi to bar | 2.0684 bar |

| 35 psi to bar | 2.4132 bar |

| 40 psi to bar | 2.7579 bar |

| 50 psi to bar | 3.4474 bar |

| 60 psi to bar | 4.1369 bar |

| 70 psi to bar | 4.8263 bar |

| 80 psi to bar | 5.5158 bar |

| 90 psi to bar | 6.2053 bar |

| 100 psi to bar | 6.8948 bar |

| 110 psi to bar | 7.5842 bar |

| 120 psi to bar | 8.2737 bar |

| 130 psi to bar | 8.9632 bar |

| 140 psi to bar | 9.6527 bar |

| 150 psi to bar | 10.3422 bar |

| 160 psi to bar | 11.0316 bar |

| 170 psi to bar | 11.7211 bar |

| 180 psi to bar | 12.4106 bar |

| 190 psi to bar | 13.1001 bar |

| 200 psi to bar | 13.7895 bar |

| 210 psi to bar | 14.4790 bar |

| 220 psi to bar | 15.1685 bar |

| 230 psi to bar | 15.8580 bar |

| 240 psi to bar | 16.5474 bar |

| 250 psi to bar | 17.2369 bar |

| 260 psi to bar | 17.9264 bar |

| 270 psi to bar | 18.6159 bar |

| 280 psi to bar | 19.3054 bar |

| 290 psi to bar | 19.9948 bar |

| 300 psi to bar | 20.6843 bar |

| 400 psi to bar | 27.5790 bar |

| 500 psi to bar | 34.4738 bar |

| 600 psi to bar | 41.3685 bar |

| 700 psi to bar | 48.2633 bar |

| 800 psi to bar | 55.1581 bar |

| 900 psi to bar | 62.0528 bar |

| 1000 psi to bar | 68.9476 bar |

| 2000 psi to bar | 137.8952 bar |

| 3000 psi to bar | 206.8428 bar |

-66x66.png)