Through this article, you will see how Elang helps ceramic industry customers achieve energy saving and consumption reduction through a vacuum system transformation.

In recent years, energy costs have continued to rise, and environmental pressure has also continued to increase.

In the ceramic industry, the vacuum system is a key supporting equipment for the mud-making process, and the energy consumption and efficiency issues behind it are often overlooked. Elang has more than 20 years of experience in the field of air compression, and has successfully noticed the core problems of the ceramic industry and brought an effective vacuum system solution: screw vacuum pump.

Conventional systems in the ceramics industry

Before contacting Elang, the ceramic industry customer was using traditional liquid ring pumps and faced three main difficulties:

1. Liquid ring pumps consume a lot of energy for the ceramic industry

The power of a single liquid ring pump can reach 45kw, resulting in huge pressure on electricity bills every year.

2. Liquid ring pumps require a lot of maintenance

Compared with the core equipment of the vacuum system modified by Elang: the screw vacuum pump, the vacuum degree of the liquid ring pump is very unstable, and frequent maintenance has affected the company’s production capacity.

3. The water consumption is very large

Compared with the screw vacuum pump, the liquid ring pump needs to use a lot of circulating water, and the cost of drainage treatment will also be very high. The pressure faced by today’s environmental audit is unimaginable.

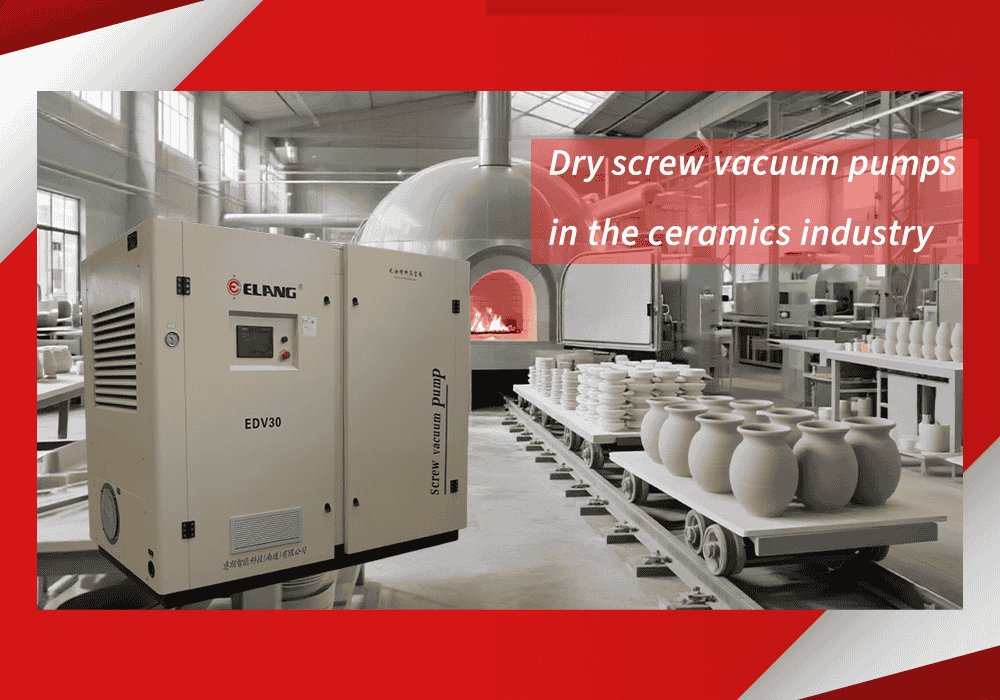

New force in the ceramics industry: dry screw vacuum pump

Elang customized a dry screw vacuum pump solution for the ceramic industry, which is green and energy-saving and equipped with intelligent control to completely replace the original liquid ring pump system.

1. Provide the factory with a long-term development direction, pursue energy saving, pass environmental protection assessment, high-quality production, and intelligent upgrade of the vacuum system.

2. The operation of the dry screw vacuum pump type is oil-free and water-free, which is more environmentally friendly than the liquid ring pump used before.

3. The screw vacuum pump equipped with a frequency converter can adjust the speed as needed, and the energy saving effect is very significant compared to the liquid ring pump.

4. The stable pumping speed is very suitable for the high-load conditions of the ceramic industry.

5. The screw vacuum pump has low working noise and small size, which improves the environment during on-site operations.

The data fed back after the transformation:

The power of a single screw air compressor: 22kw; the annual electricity consumption is 136,000 kWh, which saves 144,000 kWh of electricity compared to the previous use of liquid ring pumps.

-66x66.png)