Every year, hundreds of millions of tons of fly ash are released into the atmosphere worldwide, mainly generated by the combustion of products, especially coal. However, fly ash has now been reused, especially in the cement manufacturing process.

Adding Challenges to Environmental Protection

While this is beneficial to the environment, it adds additional steps and logistical challenges to the operations of companies that produce fly ash. They not only need to capture fly ash, typically consisting of particles smaller than 100 micrometers in diameter, but also transfer it within the factory to a location where it can be reused or transported.

Dealing with and transporting fly ash in an environmentally responsible manner, especially bulk fly ash, is not easy due to its abrasive nature (often containing a significant amount of silicon dioxide and calcium oxide) and high temperatures.

Advantages of Pneumatic Conveying Systems

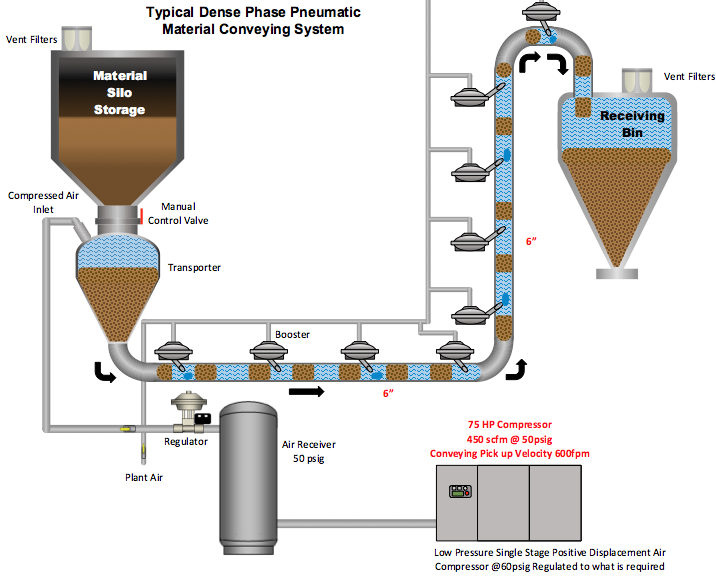

In many cases, pneumatic conveying is an ideal solution. Proper pneumatic conveying systems provide a practical, reliable, and safe method to address the challenges of transporting large quantities of fly ash. But what is a proper system?

This depends on the respective operational requirements, so any company that needs to move a large amount of fly ash should first consider its specific requirements. For example, how long is the pipeline required, where does the fly ash need to be moved, and are there any specific safety standards that need to be met? Considering the characteristics of the fly ash that needs to be transported, such as its temperature, particle size, and friction characteristics, a robust and reliable system is certainly required.

Pneumatic Conveying Method of Fly Ash

Fly ash can be pneumatically transported in different ways. The transportation of fly ash can be carried out using positive pressure (forward conveying) or vacuum (negative conveying) methods. The former uses compressed air to push the fly ash through the pipeline at the beginning of the system, while the latter inhales the fly ash to its destination. Your specific needs, such as the delivery distance of fly ash, will determine whether positive or negative conveying is more suitable.

If you choose to use a positive pressure system to transport fly ash, you will need an air compressor or blower to provide the precise flow and pressure required by the system. Using an inappropriate blower or compressor can lead to clogging, extended unloading time, and increased energy consumption. Determining the specifications of a blower or compressor for pneumatic conveying is a complex task that requires the use of special calculation software. If your current system has any of the above issues, be sure to check its specifications before investing.

Design Optimization of Your Fly Ash Conveying System

If you’re unsure about how to replace your old system with a new compressed air system, we can provide assistance. Choosing the right equipment specifications is crucial: it not only helps you save on energy costs but also reduces unloading time and helps prevent blockages. Calculating the appropriate equipment specifications is a complex task that requires specific software and expertise. We offer specification calculations to help you find the ideal pneumatic conveying system.

Contact Us

If you need to purchase an air compressor with a heat exchanger, we have products that can meet your specific requirements.

Contact[email protected]Whatsapp+86 13501890887

Based in

No. 668. Delixi Road. Nanxiang Industrial Development Zone, Shanghai, PRC.

Contact[email protected]

Whatsapp+86 13501890887

Based in

No. 668. Delixi Road. Nanxiang Industrial Development Zone, Shanghai, PRC.