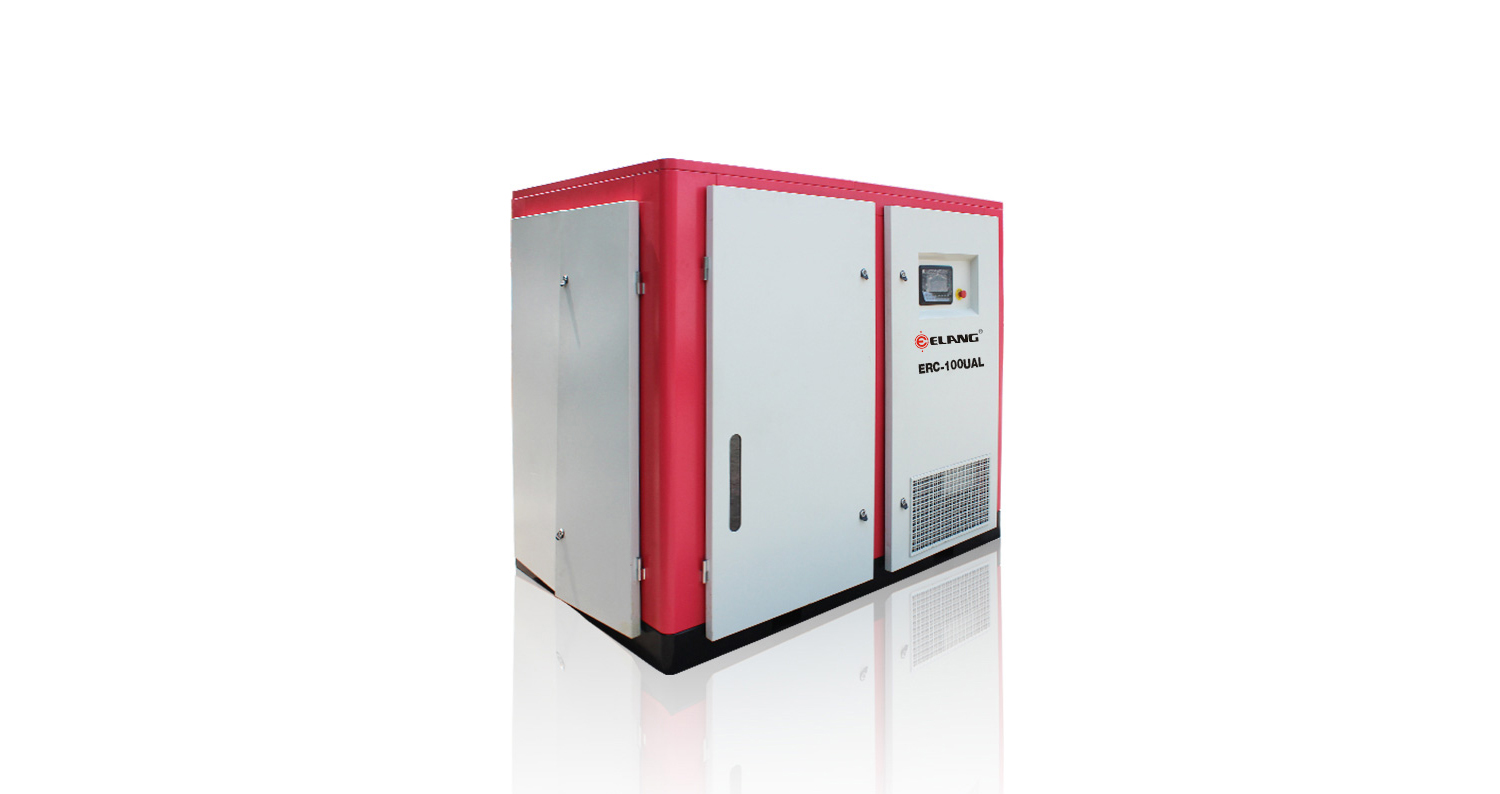

16 – 40 Bar High Pressure Screw Air Compressor

Motor Power: 45 – 355 kw

Working Pressure: 16 – 40 bar

Air Delivery: 5.2 – 35 m3/min

to become an agent. Learn more about agency policy.

More competitive agent price by FCL!

High Pressures Double Screw Air Compressor is a kind of oil-injected double screw air compressor with screw air end of high quality high pressure single-stage or two-stage type. Reliable perfomance, excellent quality, enviromental protection and energy-saving. Widely applied to the industries of mine projects, medical, food, electronics, chemical plant, mechanical and so on.

Internal display

Product Range

One type: Air delivery 6-34 m3/min, working pressure 25bar

The other type: Air delivery 5.5m3/min, working pressure 40bar

Advantages

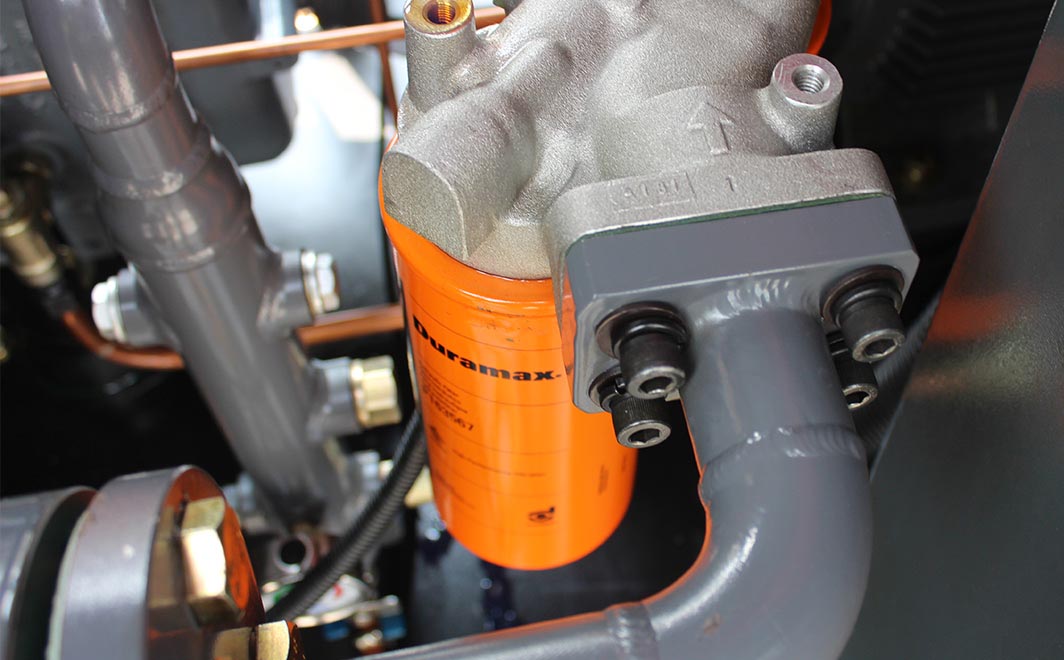

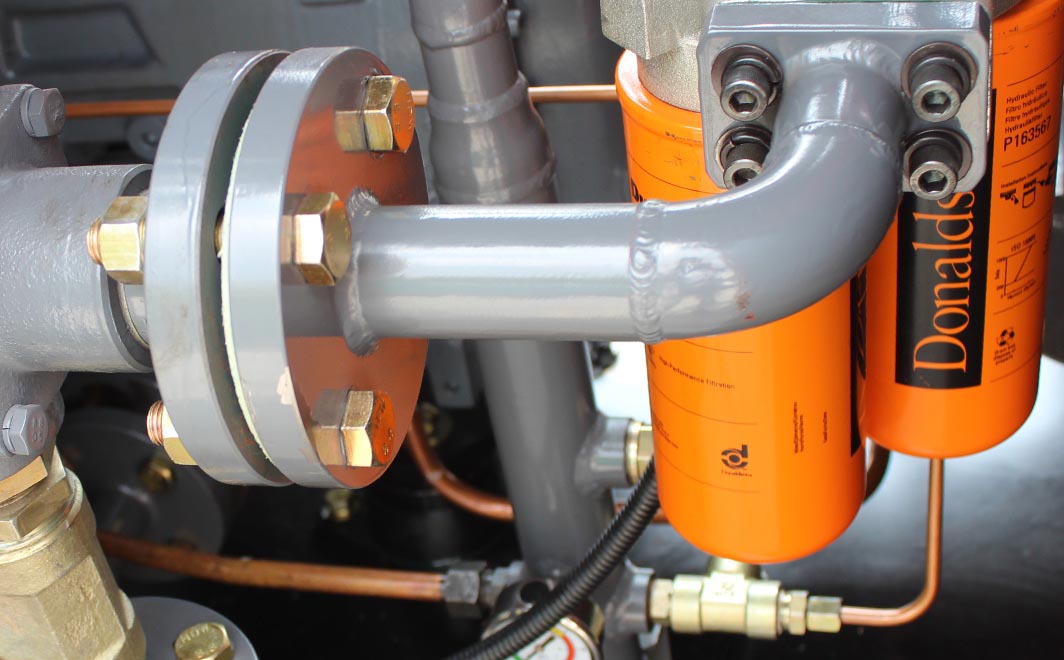

Perfect screw air end desigh parameter, accurate calculation of heat balance and linear expansion coefficient, high volume efficiency and advanced process flow. Superior product, sophisticated processing and manufacturing, and precision coordination, that can reach high efficiency and best compression ratio. The thrust bearing and radial bearing with better anti-abrasion function have more strong axial carrying capacity and stable running performance. The new inter-stage, cooling system make the compression ratio between two-stage compression higher, improve compressor efficiency, lower power consumption, save energy and protect enviroment, The wide application of unique sealing technology in the screw air end make reliability more higher and maintenance more convenient.

Powerful motor with SKF precision bearings and F insulation grade is of high protection motor, which is safe and reliable, high energy efficiency.Motor rich capacity can bear continous full-load operation without failure under all kinds of bad weather condition.

With excellent control system and ultra-strong safety protection function, the micro-computer controller of screw air compressor is the new generation high technology product developed by ELANG. It has the functions of controlling, communicating, ulttra-strong safety protection, remote control and nulti-computer control.

| Model | Exhaust Pressure | Air Delivery | Motor Power | Compression Series |

Dimension(mm) | Weight | Output pipe Diameter |

||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | Kg | |||

| ERC-60UAL | 232 | 16 | 183.6 | 5.2 | 45/60 | 1 | 1450 | 1100 | 1570 | 1800 | DN40 |

| ERC-100UAL | 232 | 16 | 303.6 | 8.6 | 75/100 | 1 | 1950 | 1150 | 1700 | 2100 | DN40 |

| ERC-150UAL | 246 | 17 | 388.4 | 11 | 110/150 | 1 | 2500 | 1500 | 1900 | 3500 | DN50 |

| 362 | 25 | 370.8 | 10.5 | 2 | |||||||

| ERC-175UAL | 246 | 17 | 459 | 13 | 132/175 | 1 | 2500 | 150 | 1900 | 3500 | DN50 |

| 362.5 | 25 | 423.7 | 12 | 2 | / | ||||||

| ERC-200UAL | 261 | 18 | 653.2 | 18.5 | 160/200 | 2 | 2750 | 1550 | 1950 | 4800 | DN65 |

| 580 | 40 | 423.7 | 12 | ||||||||

| ERC-250UAL | 580 | 40 | 441.4 | 12.5 | 185/250 | 2 | 2650 | 1600 | 1950 | 3780 | DN40 |

| ERC-270UAL | 246 | 17 | 776.8 | 22 | 200/270 | 1 | 2850 | 1750 | 2000 | 4800 | DN65 |

| 290 | 20 | 741.5 | 21 | 2 | 5000 | ||||||

| ERC-315UAL | 290 | 20 | 847.4 | 24 | 235/315 | 2 | 4000 | 2000 | 2100 | 7000 | DN65 |

| ERC-330UAL | 246 | 17 | 918 | 26 | 250/330 | 1 | 3150 | 2000 | 2000 | 5450 | DN80 |

| ERC-375UAL | 362 | 25 | 882.8 | 25 | 280/375 | 2 | 4000 | 2000 | 2100 | 7000 | DN65 |

| 435 | 30 | 805.1 | 22.8 | 7000 | DN50 | ||||||

| 580 | 40 | 706.2 | 20 | 6000 | DN50 | ||||||

| ERC-470UAL | 362 | 25 | 1165.2 | 33 | 355/470 | 2 | 4600 | 2300 | 2400 | 8000 | DN65 |

| 290 | 20 | 1235.8 | 35 | 9000 | DN80 | ||||||

|

Motor Efficiency Class:Ultraefficient/IE3/IE2 as per your required |

|||||||||||

Coming Soon …

You May Also Like

30 – 50 Bar Piston Compressor

9 – 22*3 kw @ 0.6 – 6.0 m3/min

Working Pressure: 30 – 50 bar

Learn More >>

30 – 40 Bar Oil Free Compressor

11 – 250 kw @ 1 – 21 m3/min

Working Pressure: 30 – 40 bar

Learn More >>