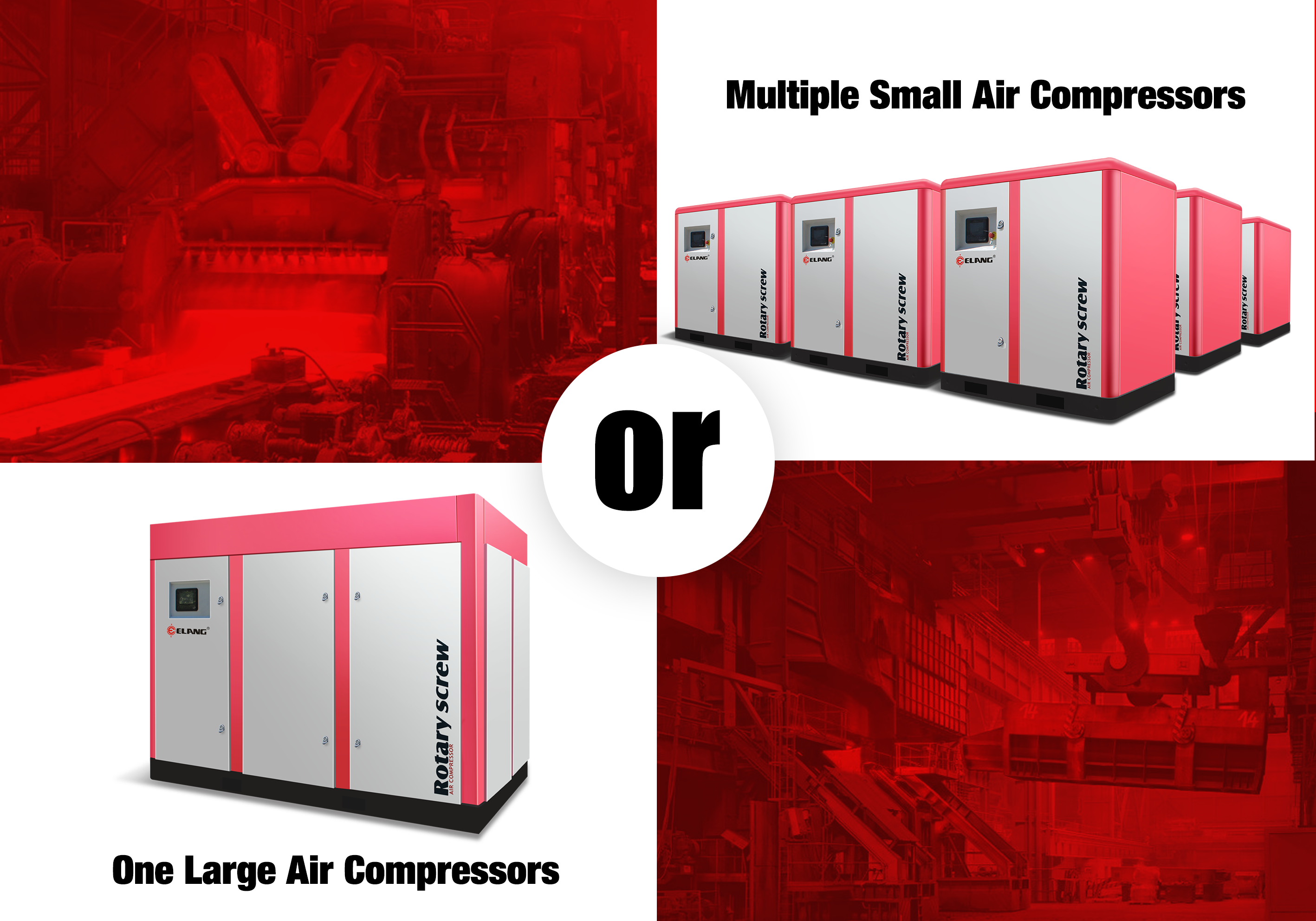

Should I choose one large air compressor or multiple smaller ones? Many customers have met this problem when selecting an air compressor solution.

Before answering this question, we first need to clarify the following points:

- Whether the shutdown of the air compressor equipment due to malfunctions affects production and results in economic losses.

- Whether there is a need to increase gas consumption in the future or add new gas production lines.

- Whether there is fluctuation in gas consumption, and if gas usage is consistent across different time periods.

- Whether the area of the air compressor station building site meets installation requirements.

- Whether the power supply equipment can meet the electrical demands of the air compressor.

By employing several smaller air compressors for gas supply, a balance between economic feasibility and gas provisioning can be achieved. In many instances, dividing the total gas consumption in half is viable. This strategy not only fulfills gas requirements but also mitigates the risk of downtime due to a single compressor malfunction, as the remaining unit can continue to provide gas, thus preventing a complete cessation of supply.

If production must remain unaffected by downtime and demands continuous gas supply, a solution involves utilizing three air compressors, each contributing 50% of the compressed air output. Two units operate as primary, with the third serving as a standby. In the event of a malfunction, the standby compressor seamlessly takes over, promptly substituting the faulty unit. Moreover, this setup ensures uninterrupted operations during equipment maintenance, guaranteeing seamless production.

Below we provide you with several solutions based on investment costs and guaranteed air consumption cases.

| Selection Plan | Max FAD 50m3/min | Max FAD 30m3/min | Max FAD 25m3/min |

| Plan 1: 1 unit of 50m3/min air compressor Investment:100% |

Air compressor runs continuously at full load, No idle time, High economic efficiency, No standby machine. |

Air compressor runs at full load for part of the time, Equipment has idle time Reduced economic efficiency. |

Air compressor 50% load, Long idle time, Further reduced economic efficiency. |

| Plan 2:2 units of 50m3/min air compressors Investment:200% |

One full load, No idle time, High economic efficiency, One unit serves as a 100% backup. |

One partial load, With idle time, Reduced economic efficiency, One unit serves as a 167% backup. |

One 50% load, Long idle time, Further reduced economic efficiency, One unit serves as a 200% backup. |

| Plan 3:2 units of 25m3/min air compressors Investment:150% |

Two full load, No idle time, High economic efficiency, No standby machine. |

One full load, one partial load, With idle time, Reduced economic efficiency. |

One full load, One standby, No idle time, High economic efficiency. |

| Plan 4:3 units of 25m3/min air compressors Investment:230% |

Two full load, One standby, No idle time, High economic efficiency, One unit serves as a 100% backup. |

One full load, one partial load, One standby, With idle time, Reduced economic efficiency, One unit serves as a 167% backup. |

One full load, Two standby, No idle time, High economic efficiency. |

From the above table, we can observe that Plan 4 has the highest investment cost, but it can adequately meet the backup gas demand with air compressors of the same model, resulting in minimal idle time. Additionally, 75% of the total costs over the air compressor’s lifecycle are energy-related. Therefore, Plan 4 is the most reasonable choice. In summary, if the budget is sufficient and uninterrupted gas supply is a requirement, opting for a backup unit is advisable.

Elang has customized gas supply solutions for many factories and received positive feedback. Below, we present just a portion of our project cases. If you would like to learn more about our cases, you can click here to explore further.

Our Case:

Aerospace Industry

Glass Manufacturing Factory

Wastewater Treatment Industry

Contact Us

If you need to purchase an air compressor with a heat exchanger, we have products that can meet your specific requirements.

Contact[email protected]Whatsapp+86 13501890887

Based in

No. 668. Delixi Road. Nanxiang Industrial Development Zone, Shanghai, PRC.

Contact[email protected]

Whatsapp+86 13501890887

Based in

No. 668. Delixi Road. Nanxiang Industrial Development Zone, Shanghai, PRC.