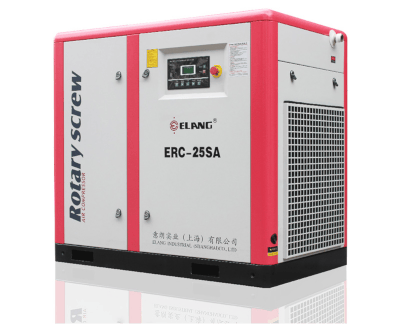

Small textile factories or low-quality processes tend to use ordinary screw compressors with filters, which are less expensive, while high-end fabrics and stable air sources require oil free air compressors.

Textile processes require no oil

1. Jet loom process

Jet looms require dry, oil-free compressed air. During the production process, fine nozzles blow compressed air generated by mechanical equipment onto the yarn bundle, creating a vortex that gives the yarn its shape, elasticity, and resilience. If the compressed air contains oil, it may contaminate the yarn and fabric, leading to issues such as oil stains, uneven dyeing, and other defects, which can affect the quality of the finished product. Therefore, oil free air compressors are typically used to provide pure compressed air.

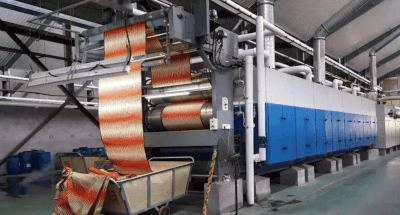

2. Printing and dyeing process

In the dyeing and printing process, compressed air is used for spraying dye and drying fabrics. However, even a small amount of oil contamination can cause a decrease in the clarity of the dyeing pattern and a reduction in colour brightness, affecting the appearance and quality of the product. Therefore, oil free air compressors are generally used to ensure the purity of the air source.

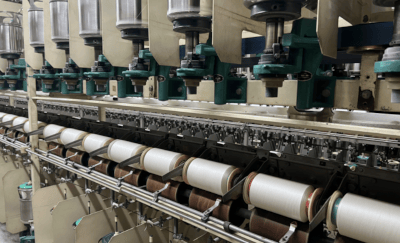

3. Spinning process

In the air-jet spinning process, oil free air compressors provide stable, clean compressed air to the fibre conveying system, ensuring that fibres are conveyed evenly and quickly to the spinning section, reducing fibre entanglement and blockages, and improving spinning efficiency and yarn quality. If the compressed air produced by the mechanical equipment used in the factory contains oil, it may cause the fibres to stick together, affecting the normal spinning process and yarn quality.

4. High-end fabric production

For some high-end fabrics, such as silk and fine synthetic fibres, the requirements for quality and feel are extremely high. From fibre processing to fabric formation, pure compressed air supplied by oil free air compressors must be used at every stage to prevent oil contamination of the fabric and ensure that its high-end quality and characteristics remain unaffected.

The necessity of oil-free air

In the textile industry, material processing stages with extremely high air quality requirements can only use oil free air compressors to avoid oil contamination adversely affecting product quality.

Weaving of long-fibre, fine-gauge, high-density fabrics

The production of this type of fabric requires a high degree of cleanliness in compressed air, so oil free air compressors are generally recommended. Since the fibres of this product are fine and the structure is dense, any oil contamination of the fabric is difficult to remove and can seriously affect the appearance and performance of the fabric. Therefore, oil free air compressors are generally used to ensure production quality.

Oil vs Oil free air compressor

The use of oil-lubricated air compressors with multiple air filters cannot completely replace oil free air compressors.

Analysis of inevitability

Oil-free compressed air filtration performance: Conventional screw air compressors inject lubricating oil during the compression process to achieve cooling, sealing, and lubrication. Despite oil-air separation and multiple filtration stages, it is still difficult to completely remove oil from the compressed air. Even high-precision oil filters can only reduce oil content to a certain extent and cannot achieve the purity level of air output from oil free air compressors.

For example, the oil content in compressed air discharged by oil-injected screw air compressors is typically controlled within the range of 3–5 ppm. Even after multiple filtration processes, it is difficult to meet the oil content standards of below 0.01 ppm required by certain highly oil-sensitive processes in the textile industry.

Stability and reliability: oil free air compressors are designed with special features, such as dry screw compressors or water-lubricated screw compressors, which fundamentally eliminate oil contamination issues, resulting in more stable and reliable operation.

In contrast, conventional screw air compressors with multiple filtration systems may experience reduced filtration efficiency if maintenance and replacement of the filtration system are not performed promptly, which can affect the quality of compressed air and, in turn, impact the quality of textile products.

The common choice in the textile industry

High-end fabric manufacturers: Companies that produce high-end fabrics such as silk and fine synthetic fibres typically opt for oil free air compressors. Any oil contamination could result in fabric defects, affecting the product’s premium quality and market value. For example, in the jet loom process, oil free air compressors ensure that yarn is not contaminated by oil, thereby guaranteeing uniform colour and surface smoothness of the fabric.

Large-scale textile companies: Due to their large production scale, large-scale textile companies have high requirements for the stability of compressed air quality and also tend to choose oil free air compressors. Although oil free air compressors have higher initial investment costs, they offer lower maintenance costs in the long term and ensure product quality stability, reducing production accidents and defective product rates caused by air quality issues. For large enterprises using highly automated textile equipment, oil free air compressors can better protect the precision components of the mechanical equipment and extend its service life.

Small-scale textile enterprises or production processes with lower quality requirements: Some small-scale textile enterprises or those producing low-end fabrics that are less sensitive to oil contamination may consider using conventional screw air compressors combined with multi-stage filtration. In production processes with relatively lower requirements for compressed air quality, such as intermittent air usage in spinning workshops, compressed air output from conventional screw air compressors after multi-stage filtration generally meets production needs.

-66x66.png)