The machine can meet the demands of overloading use and stands up to the most severe filed environment. Meanwhile, it also can reduce fuel consumption,which greatly cut down the operation cost. Subsided structure to install the oil tank, placed around each one, Increase oil reserves, make the add oil time interval longer, the weight on both sides are balanced. Tank not in the case, make the space more and not only bring convenience to maintenance service, noise is reduced accordingly, but also giving the customer a good value feeling.

Advantages

1.High reliability:

Less compressor parts, without wearing parts, so it is reliable, long life, overhaul interval is up to 40 to 80 thousand hours;

2.Easy operation and maintenance:

A high degree of automation, the operator does not have to go through a long period of professional training, can achieve unattended operation;

3.The power balance is good:

There is no unbalanced inertia force, can smoothly high-speed operation, can achieve no basic operation, especially suitable for portable compressors, small size, light weight, small footprint;

4.Strong adaptability:

With a mandatory gas transmission characteristics, the volume flow is almost free from the impact of exhaust pressure, in a wide range of speed to maintain high efficiency.

Features

1.Cummins Engine GHH Air End

The Diesel portable air compressor used Cummins Engine and GHH AIR END, make sure the air delivery and work efficiency, also meet the overload using and the most harsh field environment.

2.GHH AIR End

German GHH air end use the latest type asymmetric tooth design, big rotor, low speed, make sure the high compression efficiency, low energy consumption, performance excellence.

3.High elastic coupling straight league

Air end and Engine through the High elastic coupling straight league,No increase gear and better reliability,the rotational speed consistent with diesel engines (not more than 2200 r/min), longer life.

4.Brake

Travel mechanism of the machine increased the manual brake also can choose the automatic brake.

5.Increase the fault sound and light alarm devices

such as failure effect it will produces similar with a police car alarm

6.Low noise:

using the labyrinth ventilation system

7.Using external doors, built-in chain

so that increase the Aesthetic feeling and stereo feeling.

8.The negater style air control system is brief and reliable

It realizes the air delivery’s continuously automatic adjustment from 0 to 100%, and makes the rotation speed of diesel engine during the idling and rated rotation speed, thereby save energy.

9.German MANN air filter, oil filter and oil separator

Ensure the suction and discharge air quality of diesel engine and compressor, and the quality of lubricating oil. They help the compressor suitable to be used in poor environment, such as environment full of dusty and high humidity.

10.Heat insulation and protection

High efficient insulation sleeve is used in the discharge pipeline of diesel engine, it has the functions of heat insulation and protection, avoiding the human getting burned.

11.Satisfy low temperature or high altitude

The compressor unit is installed with air intake preheater. Moreover, to solve the problem of diesel engine which is hard to start when used in low temperature or high altitude district, the cold starting equipment such as fuel heater and coolants heater is for option.

12.Moving convenient

The compressor unit is installed with air intake preheater. Moreover, to solve the problem of diesel engine which is hard to start when used in low temperature or high altitude district, the cold starting equipment such as fuel heater and coolants heater is for option.

13.Instrument electric control system

Instrument electric control system helps the compressor adopting to work under poor environment at minus 40 degrees in the wild. It can ensure the parameters of diesel engine, such as the oil pressure, water temperature, rotation speed, oil level, discharge temperature of air compressor, discharge pressure and etc, to work normal and alarm when failed.

14.Operation, maintenance both are convenient

All kinds of safety light makes running status be clear at a glance and equipped with automatic stop and alarm lamp device. Spacious side, front and rear door make the maintenance of air filter, oil filter and check the control be more convenient. The repaired parts are within reach, easy convenience, reduced downtime.

15.Humanized Design

The traction pull-tab is suitable for different traction equipments, lifting rod can greatly reduce operating strength while its pedal frame and handle is convenient for overhaul.

16.Attractive Appearance and Anti-corrosion

The shutters on the cover make the equipment own much better Ventilation& cooling and appearance. The high-quality cold-rolled steel plates with high temperature paint outside ensure the equipment’s service durability and best anti-corrosive property.

17.Clear and Simple Pipes:

Main pipes adopt iron pipe and are not easy to damage. The exhaust pipe of screw air end uses iron and corrugated metal combined pipe, which meets air compressor vibration demands and also convenient for maintenance.

18.Tank:

subsided structure to install the oil tank, placed around each one, Increase oil reserves, make the add oil time interval longer, the weight on both sides are balanced. Tank not in the case, make the space more and not only bring convenience to maintenance service, noise is reduced accordingly, but also giving the customer a good value feeling.

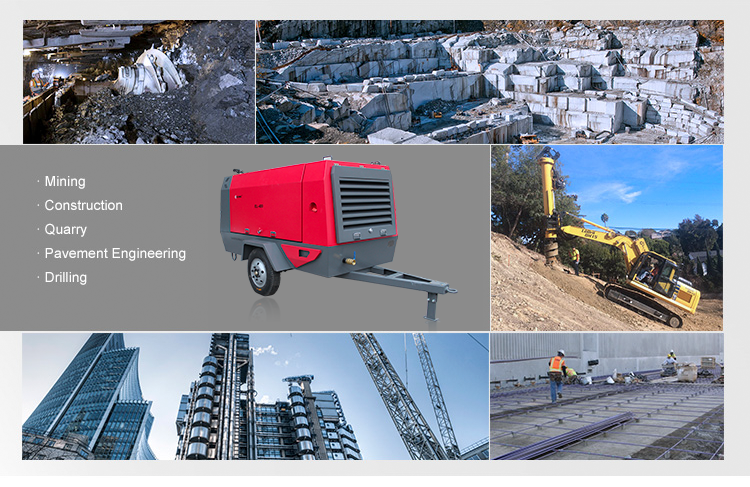

Application

| Model | Working Pressure | Air Flow | Air Outlets | Engine Brand | Engine Model |

Power | Dimension | Weight | ||

| Psig | Bar | cfm | m3/min | rpm | L*W*H (mm) | Kg | ||||

| EL185 | 100 | 7 | 185 | 5 | G1, G3/4 | Yanmar | 4TNV94L | 36.2 | 2460*1400*1430 | 1200 |

| Kubota | V1505T | 33 | ||||||||

| Weichai | WP3.2G50E347 | 36.8 | ||||||||

| EL250 | 116 | 8 | 250 | 7 | G1-1/4, G1 | Yanmar | 4TNV98C | 51.7 | 3300*1570*1570 | 1500 |

| Cummins | QSB-C80 | 60 | ||||||||

| EL350 | 116 | 8 | 350 | 10 | G1-1/4, G1 | Cummins | QSB3.9-C125 | 93 | 3800*1900*1900 | 1820 |

| 145 | 10 | 350 | 10 | |||||||

| EL400 | 116 | 8 | 400 | 11 | G1-1/4, G1 | Cummins | QSB3.9-C125 | 93 | 3800*1900*1900 | 1820 |

| 145 | 10 | 400 | 11 | |||||||

| EL460 | 188 | 13 | 460 | 13 | G1-1/2, G1-1/4 | Cummins | QSB3.9-C150 | 110 | 4000*1900*1900 | 1860 |

| EL550 | 203 | 14 | 550 | 16 | G1-1/2, G1-1/4 | Cummins | QSB5.9-C210 | 154 | 4350*1960*1950 | 2200 |

| EL660 | 246 | 17 | 660 | 18 | G1-1/2, 3*G1-1/4 | Cummins | QSB8.3-C2610 | 194 | 4580*1950*2500 | 2920 |

| EL1050 | 348 | 24 | 1050 | 29 | 2*G1-1/2 2*G1-1/41-G1 |

Cummins | QSZ13-C550 | 410 | 5400*2100*2550 | 3680 |

| EL1200 | 362 | 25 | 1200 | 34 | 2*G1-1/2 2*G1-1/41-G1 |

Cummins | QSZ13-C550 | 410 | 5400*2100*2550 | 4000 |

| 507 | 35 | 1200 | 34 | Cummins | QSK19-700 | 522 | 5400*2100*2550 | 4800 | ||

| Specifications are subject to change without notice. Cummins, Yanmar, Kubota, Perkins, Cat, Volvo, Weichai, Yuchai..etc. Level 2, Level 3, Level 4…etc for choose. |

||||||||||

Construction

Recommonded Models: EL185, EL250, EL350, EL375, EL400, EL460, EL550

Nominal Working Pressure: 7-14 bar

Air Delivery: 5-13 m3/min

Max Ambient Air Temperature: 55 ℃

Ground Engineering Drilling

Recommonded Models: EL400, EL460, EL500, EL550, EL650, EL750

Nominal Working Pressure: 7-17 bar

Air Delivery: 12-28 m3/min

Max Ambient Air Temperature: 55 ℃

Sandblasting

Recommonded Models: EL350, EL375, EL400

Nominal Working Pressure: 7-10 bar

Air Delivery: 10-22 m3/min

Max Ambient Air Temperature: 55 ℃

Blast Hole Drilling

Recommonded Models: EL550, EL650, EL750

Nominal Working Pressure: 14-21 bar

Air Delivery: 12-29 m3/min

Max Ambient Air Temperature: 55 ℃

You May Also Like

10 – 750 Hp VSD Air Compressor

7.5 – 560 kw @ 0.28 – 102 m3/min

Working Pressure: 7 – 12.5 bar

Learn More >>

2-Stage VSD Air compressor

18.5 – 355 kw @ 2.9 – 85.0 m3/min

Working Pressure: 5 – 12.5 bar

Learn More >>

Oil Free Screw Air Compressor

18.5 – 250 kw @ 2.3 – 43 m3/min

Working Pressure: 7 – 12.5 bar

Learn More >>