- Cause 1: Cooler Blockage

- Cause 2: Insufficient Compressor Lubrication

- Cause 3: Clogged Oil Filter

- Cause 4: Clogged Oil Circulation Lines in Oil-gas Tank

- Cause 5: Cooling Fan Not Working

- Cause 6: Temperature Sensor Failure or Short Circuit

- Cause 7: Temperature Control Valve Failure

- Cause 8: The Slow Circulation of Lubricating Oil

The normal operating temperature of an air compressor typically ranges between 75°C to 95°C. One of the common air compressor failure is overheating of the air compressor. For screw air compressors, operating temperatures exceeding 100°C will cause high-temperature alarms or shutdowns within the system.

So, what are the causes of overheating faults in screw air compressors and how to solve them? We take the air-cooled screw air compressor as an example.

Cause 1: Cooler Blockage

Firstly, determine whether the cooler is blocked externally or internally. Internal blockage can be checked by checking the temperature difference between the inlet and outlet pipes on the cooler. If the temperature difference is too large, it is an internal blockage. External blockage can be judged by checking how much dust has accumulated outside the cooler.

Solution: Internal blockage needs to be handled by a professional air compressor maintenance service provider. Generally, the cooler needs to be disassembled, and both sides of the cooler and the oil pipeline need to be soaked with professional cleaning agent for 20-30 minutes. Then, they need to be cleaned with a high-pressure water gun. After cleaning, installation can be completed. It’s important to note that oil should be replenished after reinstallation due to oil presence in the radiator oil pipeline.

For external blockage, low-pressure air can be used to blow and remove dust. If it cannot be blown off, it can be disassembled and washed with a high-pressure water gun or cleaned by internal blockage.

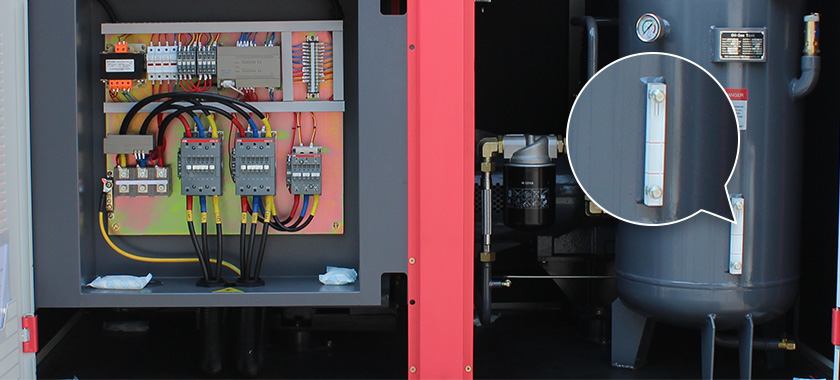

Cause 2: Insufficient Compressor Lubrication

Check the oil level sight glass on the oil-gas tank. If the lubricating oil level is below the lowest red line, it means insufficient lubricating oil.

Solution: Add an appropriate amount of lubricating oil until it reaches between the two marks on the oil level sight glass.

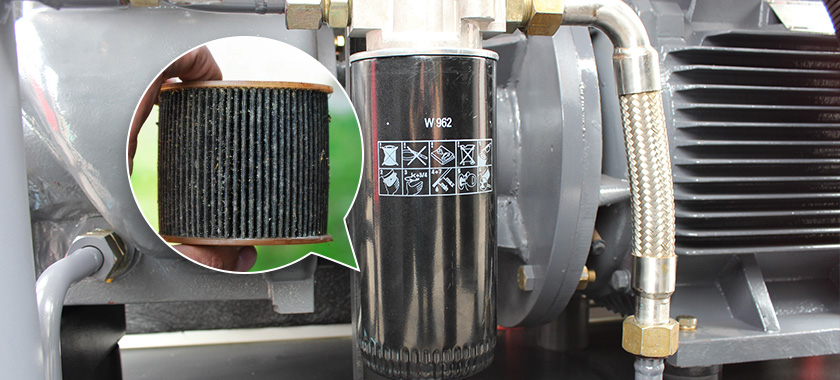

Cause 3: Clogged Oil Filter

The clogging phenomenon is due to the large temperature difference between the upper oil pipe and the oil return pipe.

Solution: Replace the new oil filter.

Cause 4: Clogged Oil Circulation Lines in Oil-gas Tank

The cause is usually due to foreign matter entering the oil-gas tank during the replacement of the oil separator, resulting in poor circulation of lubricating oil and high temperature.

Solution: Clean foreign matter in the oil-gas tank.

Cause 5: Cooling Fan Not Working

The cooling fan is usually turned on at 85 ℃ and will turn off below 75 ℃. If the temperature is high and the cooling fan does not work, it may be damaged or the cooling fan contactor may be damaged.

Solution: Replace the cooling fan, contactor, or perform maintenance.

Cause 6: Temperature Sensor Failure or Short Circuit

Solution: Replace the new temperature sensor.

Cause 7: Temperature Control Valve Failure

The function of the temperature control valve is to ensure that at low temperatures, lubricating oil circulates in a small loop without passing through the cooler. When the temperature exceeds 80°C, the temperature control valve automatically opens, allowing lubricating oil to circulate through the cooler in a larger loop.

Solution: Replace the temperature control valve core with a new one.

Cause 8: The Slow Circulation of Lubricating Oil

It may be increased viscosity of lubricating oil due to the low temperature in winter, long-term lack of replacement of lubricating oil, and the use of inferior lubricating oil, which leads to poor fluidity and poor circulation, resulting in high temperature.

Solution: Replace genuine low-viscosity lubricating oil.

In addition to the cause of the failure caused by the above, it is also necessary to check whether the inverter module is high temperature. The solution is to clean the cooling part of the inverter (purging with low-pressure air). If the panel prompts that the motor coil is high temperature, the solution is still to use low-pressure air to purge the heat dissipation part of the motor. It is specially reminded that if the operating environment temperature of the air compressor is too high, it will also cause the temperature of the equipment to increase. The solution is to use the exhaust fan duct to discharge heat and reduce the ambient temperature.

The reason we pay attention to the overheat fault of the air compressor is twofold: on one hand, it can affect the service life of the air compressor, and on the other hand, it can easily lead to the tripping of the air compressor, necessitating the prompt resolution of the overheating condition. However, when the air compressor trips, besides the factor of overheat, we often encounter other factors as well. To learn more about Why My Compressor Keeps Tripping Breaker.

-66x66.png)