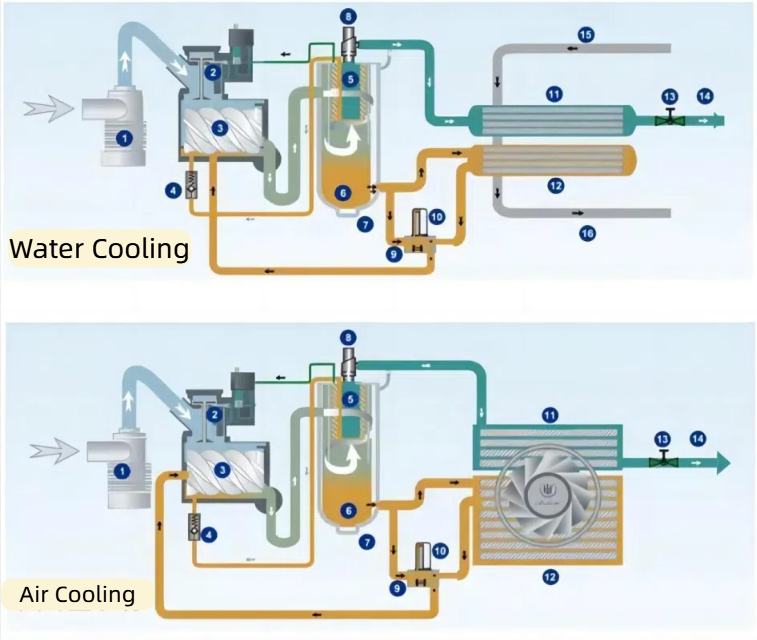

This article will explain the working principles of screw compressors by detailing the two main components of the system: the airflow (indicated in green) and the oil circuit (indicated in yellow) just as the different kinds, advantages, and applications.

What is a Rotary Screw Air Compressor?

Revolving screw air compressors utilize a turning positive relocation instrument included helical cog wheels (screws) to pack air by decreasing the volume of a chamber. Its method of activity is fairly similar to other compressor types, for example, responding cylinder and divergent compressors.

The fundamental distinction between a revolving screw air compressor vs. responding and radiating air compressors is that they convey a steady (non-throbbing) stream of compacted air and are 100% obligation cycle machines.

Screw Air Compressor Working Principle

Airflow paths–The core of system functionality

Air enters through the intake filter

Atmospheric air enters the screw air compressor through the intake filter and intake valve. The intake valve controls the volume of air drawn into the system (note: atmospheric pressure varies significantly with altitude). When the compressor is under demand or load, the intake valve fully opens. When there is no demand and the compressor is idle, the intake valve closes.

Air passes through the intake filter (1) and intake valve (2). The intake valve remains fully open during load and closed during idle.

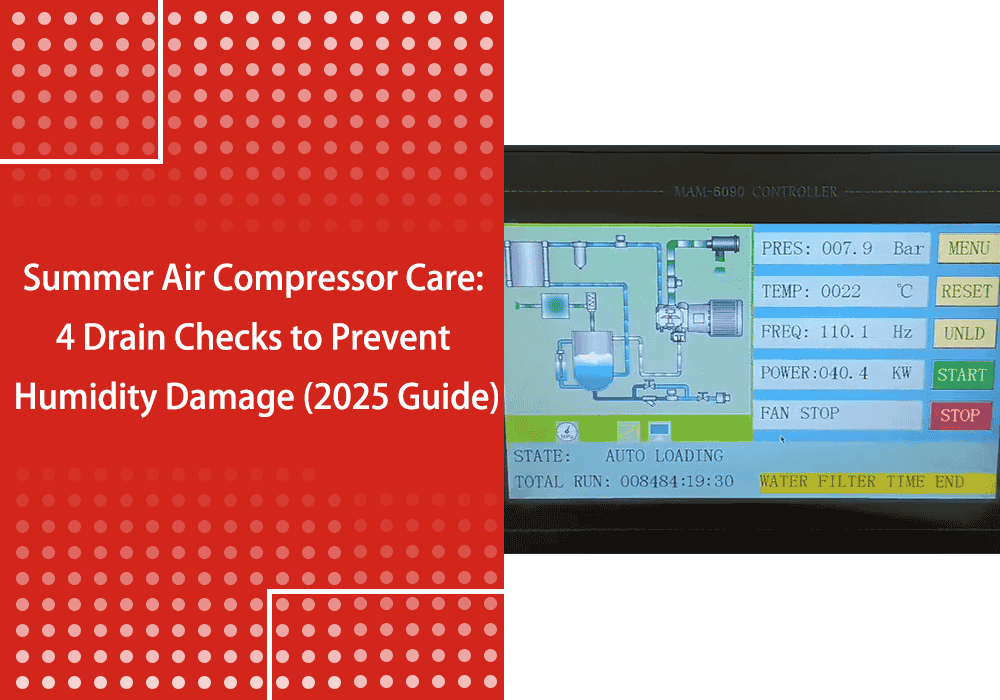

When the compressor reaches the specified pressure (unloading pressure), it releases internal pressure to reduce power consumption during idle operation. Typically, the screw compressor may switch back to load mode before completing the idle transition. If this occurs too frequently, rapid cycling may occur, potentially damaging the equipment. If rapid cycling is observed, consult a professional immediately.

After passing through the air filter to remove particulates, air enters the compression chamber via the intake valve.

Air is compressed in the air end

Here we came to the core of the working principle of screw compressor- screw rotors in the air end. As air enters the compression chamber (3), two interlocking helical rotors (screws) mesh together, trapping air between the rotors and housing.

The counter-rotating rotors reduce the gap between them, compressing the air. The male rotor is typically driven by an electric motor, which in turn drives the female rotor.

In oil-lubricated compressors, oil is injected into the compression chamber to coat the rotors. This seals gaps, reduces wear, extends screw compressor life, and lowers air and component temperatures.

The injected oil exits with the compressed air and must be removed. (Oil free air compressors skip this step and are used in applications requiring ultra-pure air.)

Oil is removed in the oil-air separator

When the oil-air mixture enters the oil sump or oil-gas separation tank (5), it impacts baffles that redirect the airflow into a centrifugal motion. This vortex effect separates most oil (6) from the air, forcing it against the tank wall (7). Residual oil is removed by a coalescing filter at the separator’s top.

Air exiting the separator contains less than 3 ppm oil, sufficient for most applications. For industries with stricter requirements (e.g., semiconductor, food & beverage, and medical equipment), additional filters can reduce oil content to 0.01 ppm.

Compressed air is still hot after separation and contains moisture, which must be removed to protect post-treatment equipment.

Air is cooled in the aftercooler

The compressed air enters an air-cooled aftercooler (11), a finned-tube heat exchanger with a fan. As the aftercooler lowers the air’s pressure dew point, water vapor condenses. Typical approach temperatures are 15–18°F.

Moisture is removed in the moisture separator

Before releasing air into the system, a moisture separator extracts condensed water, which is drained via a valve.

Depending on required pressure dew points and air quality, screw compressors may include refrigerated or desiccant air dryers. These are critical in industries like automotive, semiconductor, and electronics.

Oil circuit–The lifeblood of the system

Oil is added to the compression chamber

Lubricating oil is vital for the compressor’s lifespan. It reduces friction between moving parts and dissipates heat.

As mentioned, oil injected into the compression chamber coats the rotors, sealing gaps and preventing overheating.

Oil is removed in the oil-air separator

Centrifugal motion in the oil-gas separation tank separates most oil from the air. Oil flows down the tank wall to the sump and is recirculated. Residual oil is captured by a coalescing filter and returned via a return line.

Oil cooling and circulation

A thermostatic valve directs cooler oil back to the compressor while diverting overheated oil through a cooler. Newer variable-speed compressors route all oil through the cooler, adjusting fan speed to maintain optimal oil temperature. The lubricating oil is filtered to remove contaminants before re-entering the compression cycle.

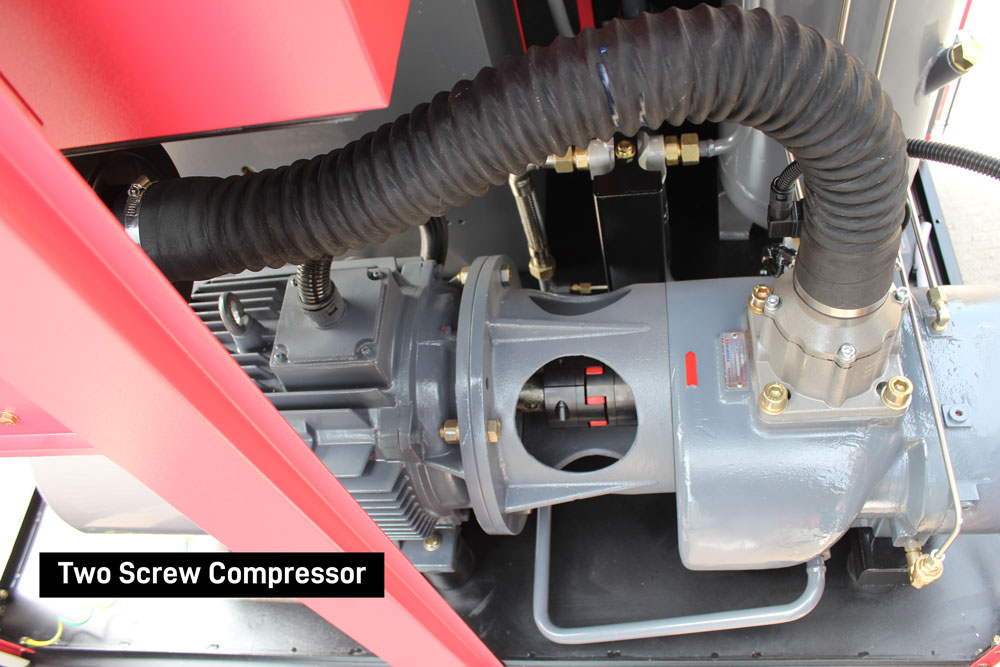

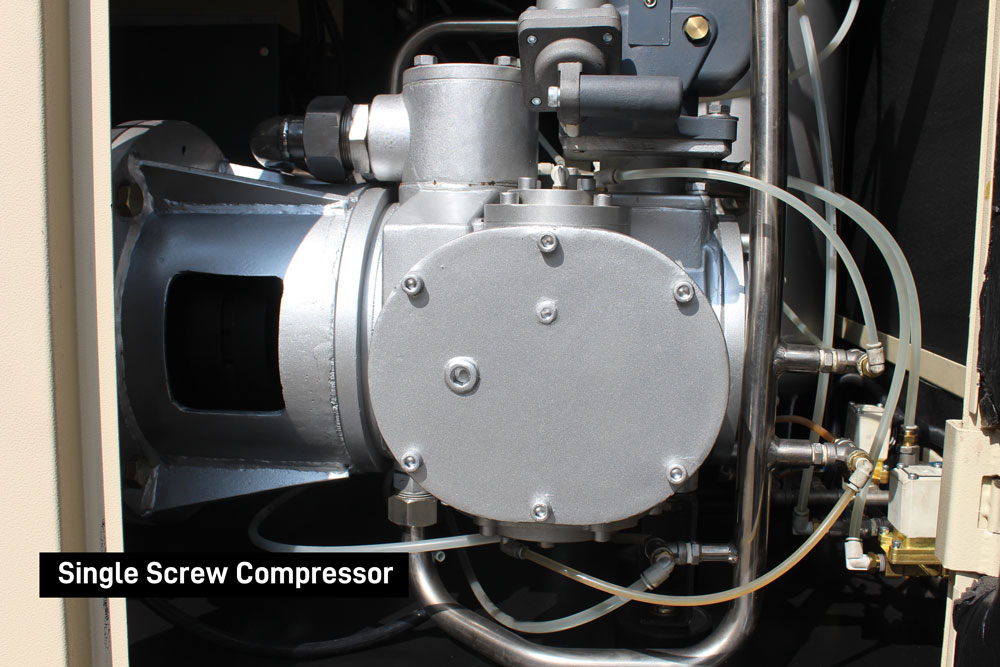

Single-screw vs. Twin-screw Compressor

Revolving screw compressors fall into two classifications relying upon the plan: single-screw and twin-screw.

Single screw air compressors (AKA ported compressors) comprise of a single fundamental screw which networks with two mating door rotors inside a metal lodging.

Twin-screw compressors contain two helical screws (one called “male” and the other “female”) that network with one another to pack air.

Screw Air Compressor Working Animation

Oil-free vs. Oil-injected Compressors

To additionally sort screw air compressors, there are oil-free and oil-injected types.

How about we investigate these variations beneath:

Oil-injected (otherwise known as oil-overflowed) screw compressors contain an ointment (oil) in the pressure chamber that brings down erosion between the moving parts. Nonetheless, the oil doesn’t just give grease; it likewise goes about as a coolant to bring down the temperature of packed air in the chamber and forestalls spillage by filling in as a pressure driven seal. Oil-free compressors don’t contain oil in the pressure chamber. Maybe, they utilize a bunch of timing gears for the turn where the mating screws don’t straightforwardly get in touch with one another.

Oil-overflowed compressors accomplish higher psig than oil-free sorts and run cooler because of the presence of oil noticeable all around end which fills in as a coolant. In any case, oil experiencing handled air can cause pollution, making oil-overwhelmed compressors unacceptable for modern cycles where a serious level of immaculateness is required.

Oil-free screw compressors by and large have lower psig than oil-injected types yet keep compacted air free of tainting — an exceptionally alluring quality in food-evaluation and drug applications.