In many manufacturing enterprises, ‘continuous operation’ is virtually an essential test that equipment must withstand, and vacuum pumps are naturally no exception. Whether in electronic ceramics, lithium batteries, pharmaceutical packaging, or food processing, any downtime of industrial vacuum pumps translates to interrupted production capacity, increased energy consumption, and process rework.

Within such production environments, the stability of vacuum systems centred around vacuum pumps becomes particularly critical.

Differences Between Screw Vacuum Pumps

Many enterprises previously utilised liquid ring vacuum pumps or rotary vane pumps. However, while the simple structure of both types facilitates maintenance, their deployment in continuous operation inevitably increases consumable usage.

Their maintenance frequency escalates with prolonged operational duration.

Liquid ring vacuum pump

Liquid ring pumps demand exceptionally high-quality working fluid; extended operation leads to scaling, resulting in diminished efficiency.

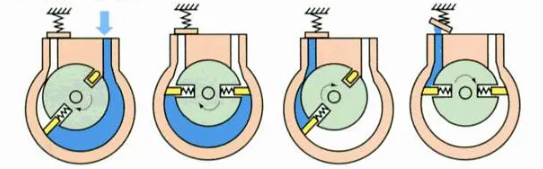

Rotary vane pump

Rotary vane pumps may also experience increased oil temperatures due to continuous operation, leading to diminished sealing performance and noticeable vacuum fluctuations.

Screw Vacuum Pump

Screw vacuum pumps provide an ideal solution to the aforementioned issues. Unlike liquid ring pumps, they eliminate concerns over impeller seal wear and the need to replenish or replace working fluids. Nor do they require the periodic vacuum pump oil and oil filter changes typical of rotary vane pumps.

Moreover, screw vacuum pumps consume 15% less energy than liquid ring pumps when achieving equivalent vacuum levels and pumping speeds. Under stable motor loads, elang’s screw vacuum pumps reduce energy consumption by 20%.

This explains why numerous enterprises opt for screw vacuum pumps – they deliver both stability and energy efficiency.

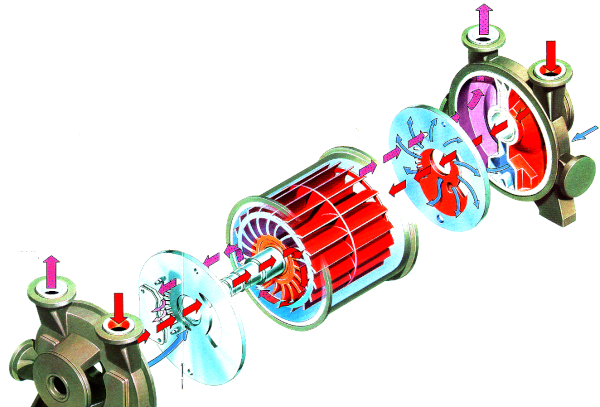

Working Principle of Screw Vacuum Pumps

The operating principle of screw vacuum pumps inherently ensures superior continuous operation compared to liquid ring vacuum pumps and rotary vane pumps.

Simply put, the working mechanism involves two intermeshing screws within the pump chamber that perform the processes of intake, compression, and exhaust—with no friction, thus eliminating wear and contamination.

Advantages of Screw Vacuum Pumps

Compared to conventional designs, it offers several reassuring advantages:

1. Sustained performance without speed degradation: The rotor operates without contact, enabling continuous operation for months without issue;

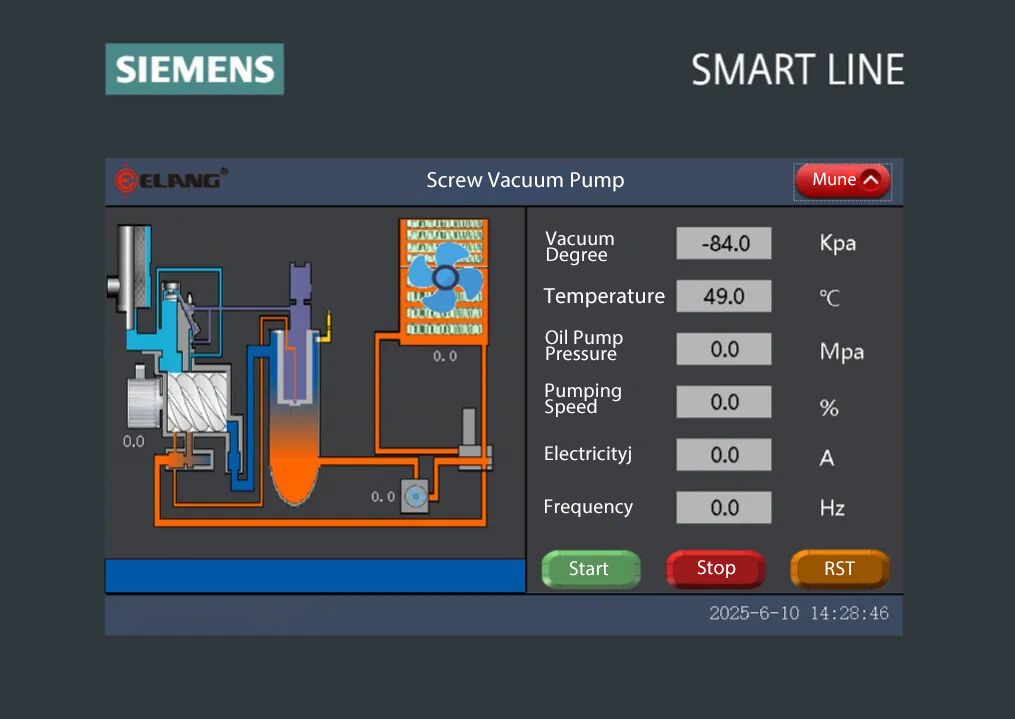

2. Vacuum Stability: As demonstrated in elang factory testing and confirmed by customer feedback, elang screw vacuum pumps deliver uniform compression and steady flow rates, maintaining exceptionally stable vacuum levels.

3. Extended Maintenance Intervals: elang vacuum pumps require only periodic inspection of cooling and sealing systems, eliminating the need for frequent shutdowns that would otherwise reduce operational efficiency.

The Use of Screw Vacuum Pumps

Elang’s equipment of this type is particularly well-suited for continuous process applications, such as ceramic degassing, lithium battery drying, and vacuum packaging. With Elang’s screw vacuum pumps, simply switch them on and they will operate reliably throughout an entire shift or even a full day.

-66x66.png)