According to our experience, we provide a brief analysis and explanation of common faults and solutions for screw air compressors.

screw air compressors, as an important part in production, have been widely used in various fields such ad textiles, metallurgy, steel industries, etc. Once a compressor is broken down, it will affect the productive efficiency, and may even lead to production safety accidents. Generally, the screw air compressor runs for a long time, and the failure rate is relatively high. Therefore, it is necessary to make the maintenance and troubleshooting work. According to our experience, we provide a brief analysis and explanation of common faults and solutions for screw air compressors.

Common Faults and Solutions for Screw Air Compressors

1. Common Faults and Causes

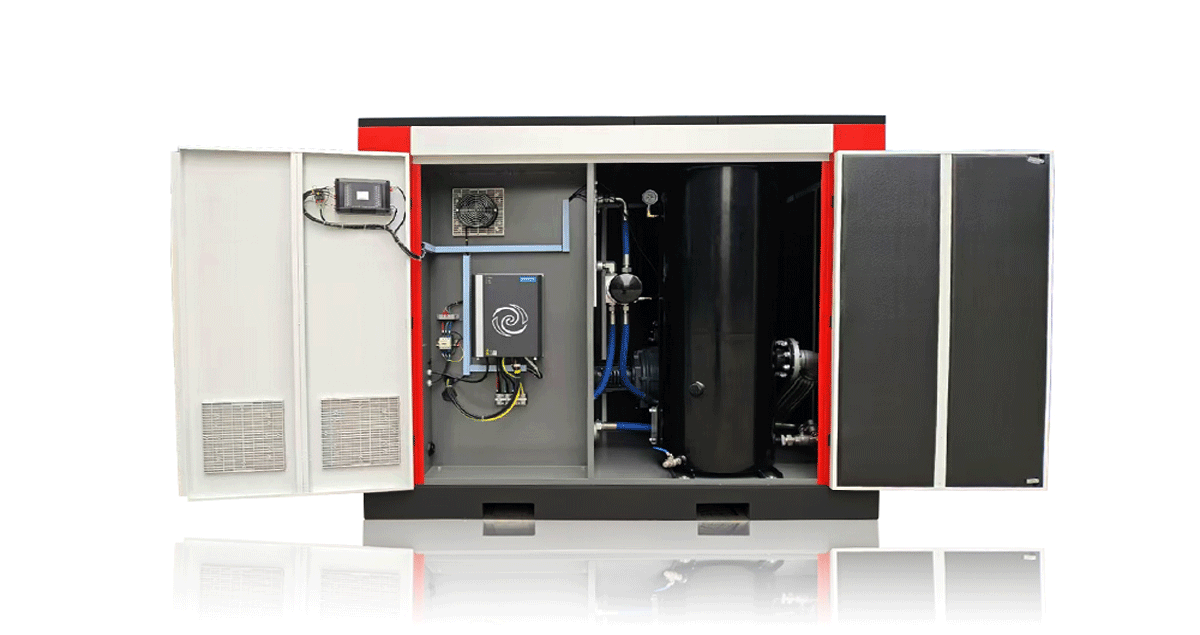

As a complicated electric system, the screw air compressor consists of an oil circulation lubrication system, an air circulation system, a water circulation system, a power distribution system and a control system. It is a device that converts the mechanical energy of an electric motor into the pressure energy of compressed air. (Learn about the basic structure of screw air compressors)

The long-term operation of the screw air compressor in industrial production leads to a higher incidence of failures. Actually, there are common types of the screw air compressor faults in production including the inability to start, abnormal pressure, insufficient discharge volume, and abnormal temperature. Generally, the failure to start the screw air compressor is often attributed to malfunctions in the control system, which can be complex due to the start-up process. Issues such as abnormal pressure and insufficient discharge volume are primarily caused by faults in the air circulation system. And worn-out components can lead to decrease sealing performance. Insufficient oil levels and high discharge temperature will also cause such air pressure problems. The abnormal temperature in the screw air compressor is caused by faults in the cooling system, which result in inadequate cooling of heat-generating components such as the electric motor.

2. Solutions to Common Problems

2.1. Insufficient Discharge Volume

Insufficient discharge volume in the screw air compressor can be caused by various factors. Therefore, when troubleshooting, it is important to investigate the possible causes of failure one by one and make corresponding solutions according to the cause of the failure.

Components Wear Failure: When the reduction of air tightness due to worn-out components as the cause of insufficient discharge volume, it is necessary to replace them in time. The main reason for the serious wear of components during long-term operation, and insufficient lubrication caused by oil shortage is also an important reason for severe components wear. Therefore, when component wear failures occur, it is typically necessary to inspect the oil circulation system of the screw air compressor simultaneously.

As some component wear may not be easily detectable, a common practice is to add oil into the cylinder and ensure that the oil level reaches at least one-third above the oil mark. Then, the screw air compressor is started, and if no abnormal noises such as knocking sounds are heard during operation, it indicates that the equipment can operate normally without significant wear on other components.

Insufficient Oil Levels or Poor Oil Quality: The appropriate level and quality of lubricating oil are crucial for the normal temperature operation of the screw air compressor. When the oil level is insufficient, it is necessary to add lubricating oil promptly until it reaches the appropriate oil mark. In cases of poor oil quality, the lubricating oil in the air compressor should be replaced. Generally, it is recommended to replace the lubricating oil every 500-800 hours of operation.

Excessive Discharge Temperature: It is usually caused by factors such as insufficient smoothness of the valve plate. In such cases, the valve plate needs to be ground or replaced to ensure proper sealing of the valves. Additionally, since screw air compressors produce a lot of heat during operation, it is important to maintain the ambient temperature below 40 degrees Celsius to ensure normal operation.

2.2. Abnormal Temperature

The abnormal temperature of the screw air compressor is mainly caused by the cooling system fault. The scaling and blockage in the cooling system, as well as the entry of air, can result in the system failure. When the temperature is abnormal, the first step is to check whether there is air entering the cooling system. If no air entering, check the scaling and blockage in the cooling system and take appropriate measures to remove the scaling.

We can take several measures to prevent the failure of the cooling system and abnormal temperature in the screw air compressors. Generally, a protective shell can be installed on the water meter at the cooling outlet pipe to prevent the entry of air. In addition, the cooling core of copper corrugated bellows in the cooling system should be replaced regularly to improve the quality of cooling water and effectively avoid scaling.

Carbon accumulation is also one of the important reasons for abnormal temperature in the screw air compressor. To prevent carbon deposits, it is necessary to clean them promptly in the air compressor. Additionally, ensuring a proper oil supply and high-quality lubricating oil, and maintaining a clean operating environment, are effective measures to slow down the formation of carbon deposits.

3. Screw Air Compressor Maintenance

To ensure the efficient and stable operation of the screw air compressor, in addition to timely troubleshooting when the air compressor fails, it is more important to maintain the air compressor. The maintenance strategies for an air compressor can be divided into four parts: preventive maintenance, overall maintenance, daily maintenance, and scheduled maintenance, based on variations in maintenance objectives, maintenance items, and maintenance methods. The maintenance strategies for an air compressor have overlapping maintenance contents, which significantly enhance the reliability of the maintenance strategies. This ensures timely detection of faults and consistently maintains the screw air compressor in its optimal operating condition.

3.1 Preventive Maintenance

Preventive maintenance refers to the preventive inspection and maintenance for all kinds of problems and failures that may occur in the operation of screw air compressors. It involves taking effective preventive measures to prevent faults from occurring before the screw air compressor experiences any failures. Depending on the different implementation strategies of preventive maintenance, it can be further divided into two parts: regular maintenance and status maintenance. Regular maintenance involves conducting overall maintenance on the air compressor after it has been in operation for a certain period, aiming to restore it to its optimal condition. While status maintenance involves determining the corresponding maintenance dates by monitoring the actual operating status of the screw air compressor. It includes performing the necessary maintenance operations when the operating condition of the screw air compressor decreases seriously.

3.2 Overall Maintenance

Overall maintenance refers to the comprehensive and integrated maintenance of the screw air compressor at regular intervals. Generally, maintenance items are extensive and primarily encompass activities such as oil replacement, circuit inspection, and component replacement. Usually, after 50 hours of operation, it is necessary to conduct a comprehensive inspection of the control circuit. After 500 hours of operation, the lubricating oil and return valve of the screw air compressor need to be replaced. After 6 months of operation, it is necessary to rewire the air compressor, etc. Overall maintenance is a comprehensive maintenance procedure performed on the screw air compressor within the designated maintenance period. It should be conducted after releasing all pressure from the equipment and dismantling it. This process effectively enhances the reliability and safety of the equipment, ensuring its normal operation.

3.3. Daily Maintenance

Daily maintenance is the maintenance and inspection work in the daily operation environment of the screw air compressor, and is generally responsible for dealing with simple faults and problems existing in the screw air compressor. For example, timely addition of lubricating oil when the oil level of the air compressor decreases, inspecting and replacing components for wear and gas leakage when abnormal noise occurs, testing and inspecting the circuit connections and control logic of the equipment controller, as well as wiping and cleaning the surface of the air compressor to remove dirt and dust. Daily maintenance ensures that the air screw compressor operates in its optimal condition. Maintaining the oil level ensures an adequate oil supply for the equipment, while keeping the equipment’s surface clean effectively prevents corrosion and enhances heat dissipation, all of which contribute to improving the operational efficiency of the equipment.

3.4. Scheduled Maintenance

Scheduled maintenance refers to the maintenance strategy for the screw air compressor at fixed intervals. Unlike overall maintenance, scheduled maintenance typically focuses on specific maintenance items that are tailored to the equipment’s needs. Based on the different maintenance intervals, scheduled maintenance can be further divided into monthly maintenance, quarterly maintenance, viscosity maintenance, etc. The maintenance frequency determines the specific maintenance targets.

Generally, monthly maintenance for the screw air compressor includes the following items: inspecting the hoses of the air compressor for signs of aging or cracks and replacing them if necessary, checking the exhaust temperature of the air compressor to ensure it is within the normal range, verifying that the lubrication of the compressor’s bearing is sufficient, and cleaning the surface of the equipment to remove any dust or dirt buildup.

Quarterly maintenance for the screw air compressor primarily includes the following items: checking if the lubricating oil of the air compressor meets the required oil standard and if its quality is satisfactory, and adding or replacing the lubricating oil if necessary. It also involves cleaning the oil filter and air filter.

Viscosity maintenance primarily involves disassembling and cleaning core components such as the oil cooler and air cooler of the air compressor. It also includes replacing critical worn-out components such as valve bodies and sealing rings.

Screw air compressors are crucial industrial equipment in industries such as steel, chemical, and textile, providing compressed air and power for various industrial processes. The reliability and stability of air compressors are of great importance to industrial production. This article addresses common air compressor failures and provides corresponding solutions. It also proposes maintenance strategies based on actual operational conditions, which are essential for ensuring the safety and stability of air compressor operation.