The installation of a screw air compressor can be divided into four aspects: environmental requirements, ground placement requirements, piping installation, and electrical safety considerations.

Environmental Requirements

1. The air compressor should be installed in a surrounding environment that is cool, has low humidity, and is relatively dust-free. If installation in a hot or dusty environment is unavoidable, it is necessary to use ducting to draw air from a cooler and less dusty area, while also minimizing air humidity.

2. The ambient temperature should be below 40°C. If it exceeds 40°C, measures should be taken to enhance ventilation and prevent high-temperature shutdown.

3. Sufficient space should be allocated around the compressor for maintenance and component disassembly.

Ground Placement Requirements

1. Due to the minimal vibration of a screw air compressor, it can be installed on a flat and firm surface. Placing the compressor on a level ground is sufficient. It is advisable to use rubber anti-vibration pads or wooden boards with a thickness of 8 to 15mm to enhance shock absorption and noise reduction.

2. The reference surface for leveling should be a parallel surface to the ground, such as the machining surface or base surface. Use a spirit level to measure the horizontal alignment, and it is recommended to keep the vertical and horizontal alignment within a range of 0.2mm/m.

Piping Installation

1. Before installation, the pipes connected to the machine must be cleaned internally to ensure there is no presence of floating rust, slag, weld beads, or other debris.

2. The gas pipelines and fittings should have an allowable working pressure that exceeds 1.5 times the rated discharge pressure or 0.1 MPa, whichever is greater, and it should be higher than the set pressure of the safety valve.

3. The piping should be designed with a certain degree of slope to facilitate the proper drainage of condensed water.

3.1. The pressure drop in the piping should not exceed 5% of the set pressure of the air compressor. The pipe diameter should not be arbitrarily reduced. If it is necessary to reduce or enlarge the diameter, gradual transition fittings should be used to avoid significant pressure loss at the joints.

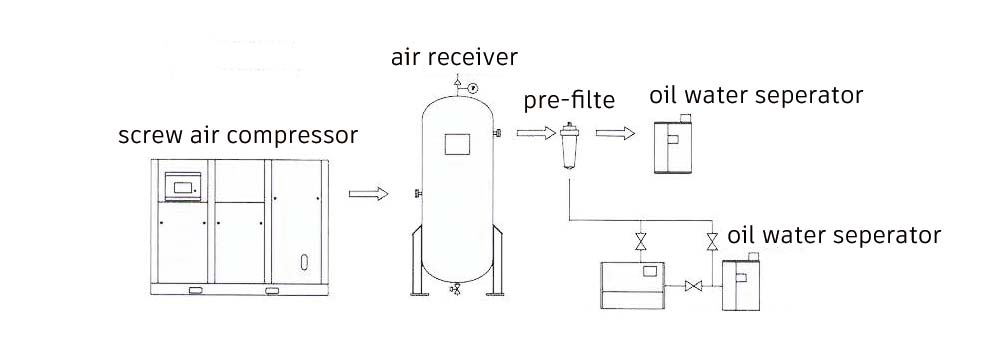

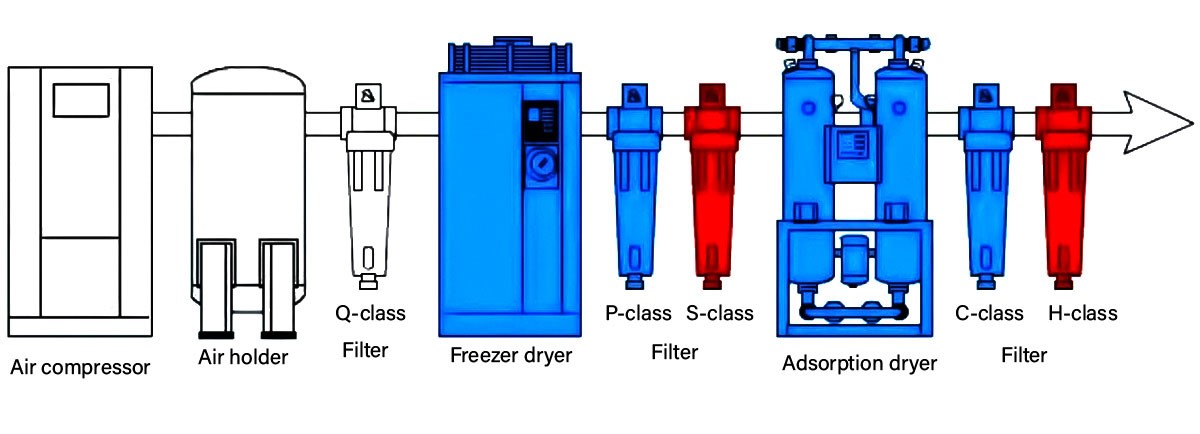

3.2. For systems with significant fluctuations in air consumption, it is recommended to install additional buffer and purification facilities. This will reduce the number of load cycles for the air compressor. An ideal configuration includes: Air Compressor – Air Receiver – Dryer.

Suggestion for standard configuration of air compressors

4. Minimize the use of elbows and valves in the piping system to reduce pressure losses.

5. In cases where there are multiple and dispersed air-consuming devices, the main pipeline should be strategically placed around the entire plant, ensuring that compressed air can be accessed from two directions at any given location, thus minimizing pressure drop.

6. Branch pipes should be directed above the main pipeline to prevent the flow of condensed water into air-consuming equipment.

Air Compressor Installation Guidance Video

Electrical safety

1. Avoid paralleling the air compressor with high-power-consuming equipment to prevent excessive voltage drops or unbalanced three-phase currents, which could cause the electrical protection devices of the air compressor to trip and stop.

2. Select the appropriate power supply cable that matches the motor power to avoid overloading the cable and the potential risk of burnout.

3. Ensure that the air compressor is reliably grounded to prevent hazards caused by electrical leakage.

4. Maintain balanced three-phase currents, with a difference of no more than 5% between the lowest and highest phase currents, and ensure that the voltage drop does not fall below 5% of the rated voltage.

5. Provide insulation protection at the power supply line inlet to prevent damage and electrical leakage resulting from friction.

6. When installing and performing maintenance, always disconnect the power supply and place a warning sign at the power switch. The power switch should be located away from the work area, and the load end of the switch should be removed to ensure personal safety.

Contact Us

If you need to purchase an air compressor with a heat exchanger, we have products that can meet your specific requirements.

Contact[email protected]Whatsapp+86 13501890887

Based in

No. 668. Delixi Road. Nanxiang Industrial Development Zone, Shanghai, PRC.

Contact[email protected]

Whatsapp+86 13501890887

Based in

No. 668. Delixi Road. Nanxiang Industrial Development Zone, Shanghai, PRC.