The petroleum industry is a major user of energy production and energy consumption. Air compressors are widely used in the petroleum & chemical industry to reduce energy consumption costs and improve production efficiency.

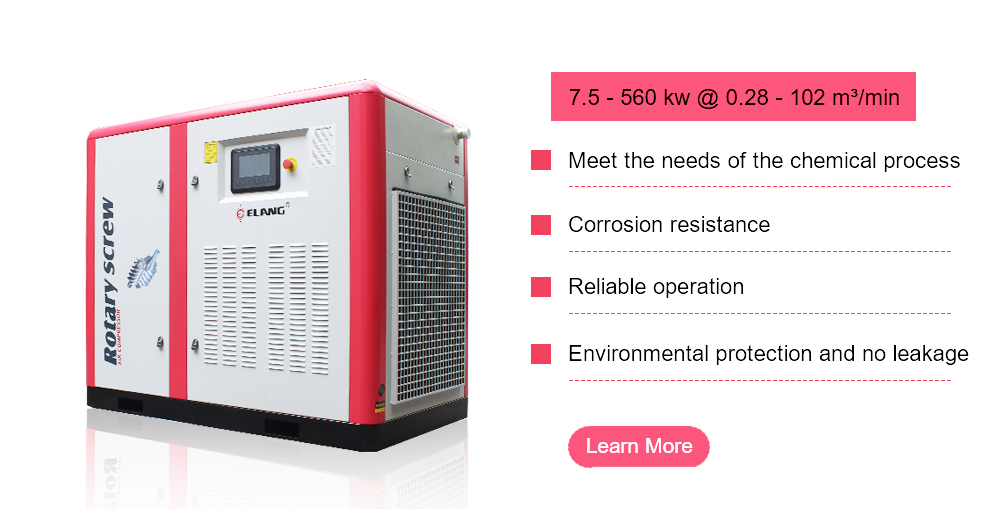

Air compressor for petroleum & chemical industry contains some special requirements.

1. Meet the needs of the chemical process.

In the chemical production process, compressor transports gas and provides the necessary material of transmission (pumping) for the system. In order to be stable, balanced in the chemical reaction process and meet the pressure required for the chemical reactions, the compressor’s discharge volume should be relatively stable. If the production fluctuations are affected due to certain factors, the compressor pressure and export pressure can also be changed to meet the requirements of the process.

2. Corrosion resistance

The media including raw materials and intermediate products is mostly corrosive, which is from the air compressor for petroleum & chemical industry. If the compressor uses inappropriate material, spare parts will be corroded and out of work. For some gas media, if there is no appropriate corrosion-resistant metal materials, non-metallic materials can be used. When selecting materials, the manufacturer must consider its corrosion resistance, its mechanical properties, cutting property and price.

3. Reliable operation

The media including raw materials and intermediate products is mostly corrosive, which is from the air compressor for petroleum & chemical industry. If the compressor uses inappropriate material, spare parts will be corroded and out of work. For some gas media, if there is no appropriate corrosion-resistant metal materials, non-metallic materials can be used. When selecting materials, the manufacturer must consider its corrosion resistance, its mechanical properties, cutting property and price.

4. Environmental protection and no leakage

Gas media from the air compressor for petroleum & chemical industry is flammable, explosive, toxic and harmful. Therefore, the compressor requires no leakage, good sealing, routine maintenance.

-66x66.png)