A reasonable design of the compressor room is particularly important, the performance of the compressor as well as the life of the compressor have a great degree of influence, then we need to focus on what requirements? An air compressor room that meets the standards needs to include multiple factors such as fire prevention, environment, and room layout.

Meeting Fire Safety Standards

Firstly, compressor rooms should be designed so that the walls, ceilings, floors and doors comply with fire rating F30. In addition, the storage of flammable and explosive liquids and gases should be prohibited inside the room. Non-combustible materials should be used for the ground around the air compressor. Combustible materials should not be stored within at least 3 meters of the air compressor. Furthermore, flammable facilities such as wiring should not be installed above the air compressor.

Maintaining Favorable Environmental Conditions

Compressor Room Layout Requirements

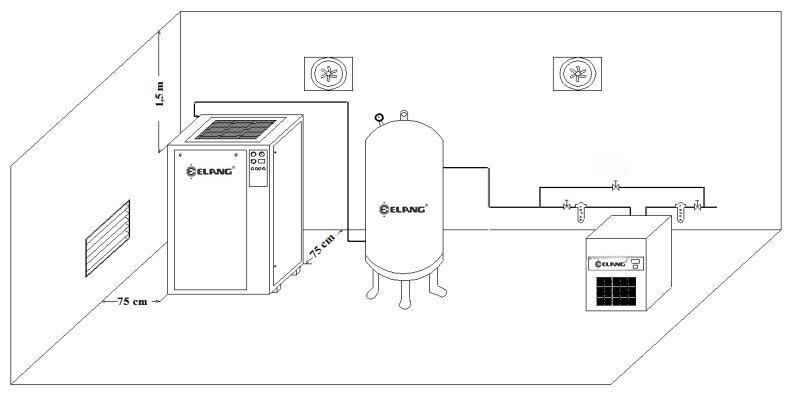

There are several considerations in designing a room layout:

1. Under the walls of the compressor room, it is recommended to install dust-proof metal screens with a mesh size not exceeding 0.5mm as air inlets, ensuring that the screen area is as large as possible.

2. A heat exhaust fan is to be installed above the side wall of the room opposite the large air inlet.

3. The floor of the compressor room needs to be flat, stable, clean, free of standing water, and may be painted off-white or green and cleaned at least once a week.

4. The exhaust outlet of the air compressor needs to be equipped with a wind scooper, which should have a diameter larger than the exhaust diameter of the air compressor. There should be no more than two bends, and it needs to be guided outside the compressor room and protected from rain and backflow.

5. If the length of the wind scooper is greater than 5 meters, axial flow fans should be added for assistance in exhaust.

6. The wind scooper should be easily detachable and located 1 meter away from the air compressor exhaust outlet.

Recommended for You

The placement and design of a compressed air system is a task that requires careful consideration, taking into account the design of the compressor room, its location, infrastructure, ventilation, and potential future expansions. These factors can determine the performance and efficiency of the compressed air system.

-66x66.png)