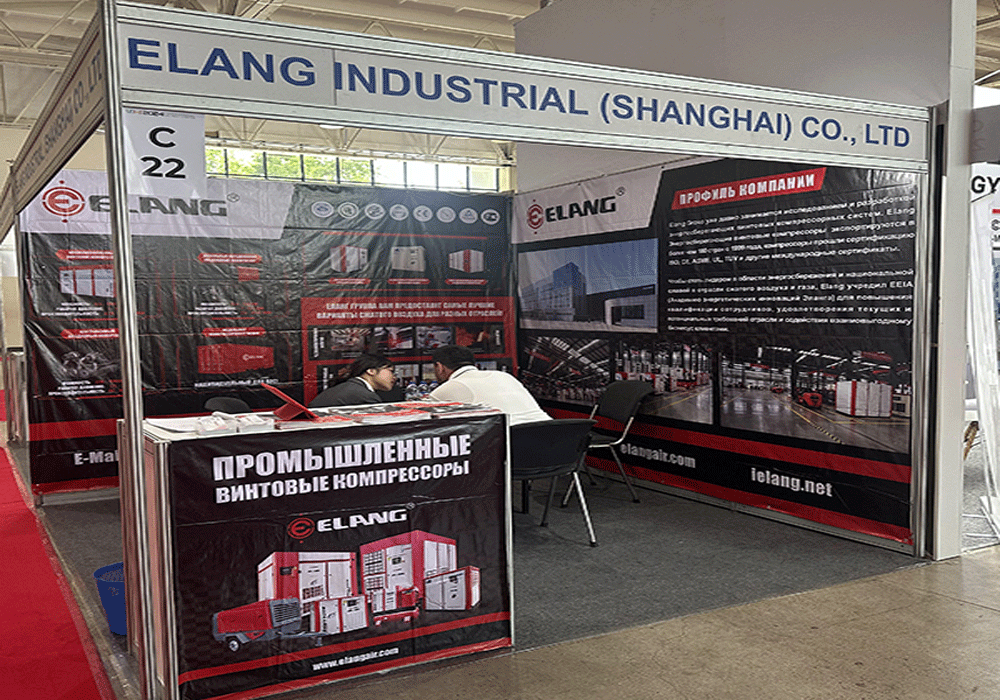

2024 International Machinery Exhibition UZ (Uzbekistan)

ELANG Co., Ltd. participated in the 2024 International Machinery Exhibition held in Uzbekistan from June 12 to June 14. Our company's exhibition booth is at No. 22, Zone C. This grand exhibition attracted exhibitors from industries such as fluid transmission, compressed air and vacuum, internal logistics and supply chain, heavy machinery, industrial subcontracting, and lightweight construction, [...]