10 – 750 Hp PM VSD Screw Air Compressor

Motor Power: 7.5 – 560 kw

Working Pressure: 7 – 12.5 bar

Air Delivery: 0.28 – 102 m3/min

to become an agent. Learn more about agency policy.

More competitive agent price by FCL!

oil injected air compressorvsd air compressorcompressor in hydropower stationcompressor for injection molding industrycompressor for PET bottle blowing industrycompressor in military enterprisescompressor for rubber manufacturingcompressor for paper industrycompressor for paper industrycompressor for woodworking industry

The permanent magnet synchronizing variable frequency compressor is a highly advanced and efficient compressor that incorporates the latest technology in its design. Only a few advanced countries and zones in the world currently possess this technology. It represents a high-end trend for future compressor development, as it has broken through traditional concepts of compressor design and incorporates sophisticated and energy-saving technical factors.

What are the differences between PM air compressors and traditional air compressors?

Advantages:

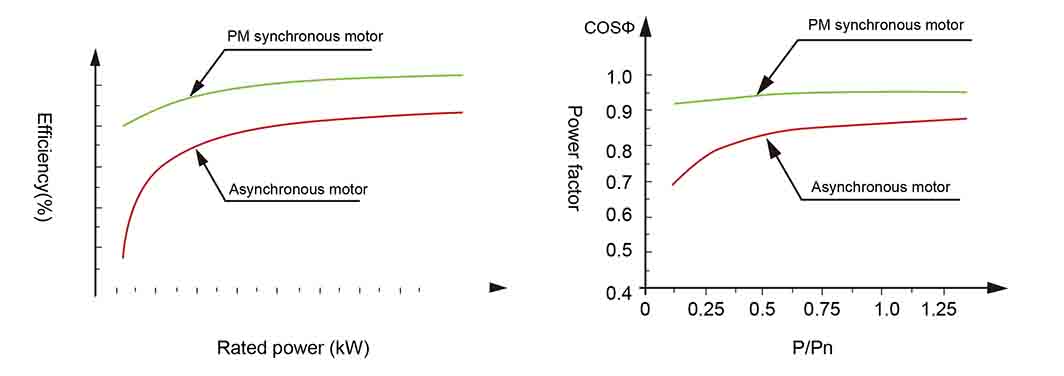

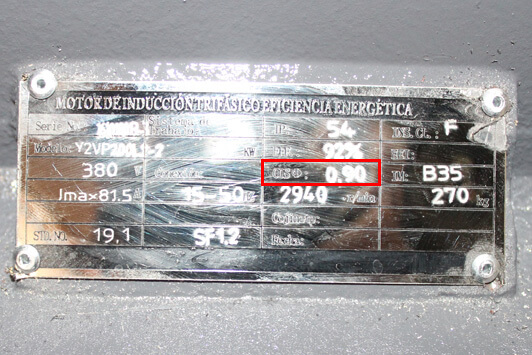

PM motor has 2~ to 7% higher working efficiency than three-phase asynchronous motor. No matter in underloading or overloading conditions, PM compressors keep high working efficiency while three-phase asynchronous motor will have fluctuant efficiency according to the loading conditions. Therefore, compressors with PM motor will save 8% to 30% energy than those with three-phase asynchronous motor.Specialized PM motor has power factor large than 0.95, even close to 1 in some models. Moreover, PM compressors are installed with frequency converter to realize variable frequency starting and decrease the impact to compressor unit and power grid during starting, so as to save operation costs.

1.servo air compressor is a modern new technology air compressor with novel and beautiful appearance.

2.Internally efficient, energy saving!

3.Small machine size, Silent ,durable and run smoothly!

4.Save many troubles of regular maintenance and replacement.

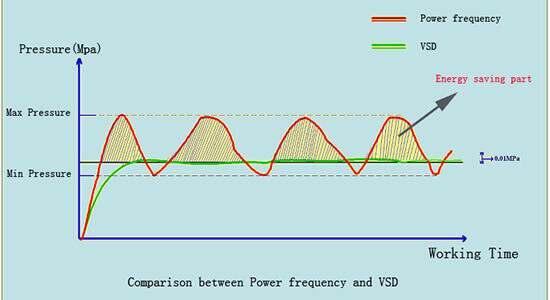

How To Save Energy?

1)The efficiency of the PM motor is always maintained at the level of about 0.95, the power factor is close to 1, and it is increased by 5%-10% compared with the same specifications of the asynchronous motor . The motor is always maintained high efficiency whatever at a light or heavy loads.

2)Variable Frequency start, reducing the energy consumption of air compressor start, a substantial reduction in starting current and maximum power load, saving a lot of electricity, allowing unlimited start and stop, and does not affect the motor life.

3)The comprehensive energy saving of servo air compressor reach the rate of 20% -35%, power saving is considerable. Machine efficiency is more 12% to 18% than ordinary air compressor, and it belongs to IE3 energy efficiency standards,The increasing purchase cost is generally recovered within 1 year!

Example: Rated power 30kW screw air compressor

Normal screw compressor has three losses:

A.Unload loss

B.Pressure loss

C.Motor efficiency loss

A. Unload loss=25% unloading time*The loss of the current load during no-load time (45%):

Unload loss=0.25*(0.45*1.2*30*5600)*0.16= 3628.8 USD/Year

B. Pressure loss=75% loading time* The loss of the pressure loss(2bar/14%)

Pressure loss=0.75*(0.14*1.2*30*5600)*0.16=3386.88USD/Year

C. Motor efficiency loss: 30kw The servo motor is about 5% higher than the normal motor:

motor efficiency loss=30*1.2*5600*0.05*0.16=1612.8USD/Year

Total cost savings: 3628.8+3386.88+1612.8=8628.48USD/Year

Total cost of normal 30kw air compressor: Cost of 75% loading time + Cost 25% unloading time

=0.75*1.2*30*0.16*5600+0.25*0.45*1.2*30*0.16*5600

=27820.8USD/Year

Power saving reached:8628.48/27820.8=31%

Application

Project

4 Units of 280kw 8bar PM Screw Air Compressor for Thermal Power Plant

11 Units of Water Cooling PM VSD Air Compressors

3 Units of Elang 330HP Screw Compressor for Chemical Industry

| Model | Working Pressure | Air Delivery | Motor Power | Dimension(mm) | Weight | Output pipe iameter |

||||

| psig | bar | cfm | m3/min | Kw/hp | L | W | H | Kg | ||

| ERC-10SA | 100 | 7 | 15.5 – 38.8 | 0.44 – 1.1 | 7.5/10 | 850 | 640 | 880 | 350 | 3/4″ |

| 116 | 8 | 14.1 – 35.3 | 0.4 – 1.0 | |||||||

| 145 | 10 | 12.0 – 30.3 | 0.34 – 0.85 | |||||||

| 181 | 12.5 | 9.9 – 24.7 | 0.28 – 0.7 | |||||||

| ERC-15SA | 100 | 7 | 25.4 – 63.6 | 0.72-1.8 | 11/15 | 1150 | 750 | 1180 | 450 | 3/4″ |

| 116 | 8 | 24.7-58.3 | 0.7-1.65 | |||||||

| 145 | 10 | 21.2-53.0 | 0.6-1.5 | |||||||

| 181 | 12.5 | 18.4-45.9 | 0.52-1.3 | |||||||

| ERC-20SA | 100 | 7 | 33.9 – 84.7 | 0.96 – 2.4 | 15/20 | 1150 | 750 | 1180 | 460 | 3/4″ |

| 116 | 8 | 31.7 – 77.6 | 0.88 – 2.2 | |||||||

| 145 | 10 | 29.7 – 74.2 | 0.84 – 2.1 | |||||||

| 181 | 12.5 | 25.4 – 63.6 | 0.72 – 1.8 | |||||||

| ERC-25SA | 100 | 7 | 47.8-109.5 | 1.2-3.1 | 18.5/25 | 1200 | 850 | 1280 | 665 | 1 1/4″ |

| 116 | 8 | 41.0-102.4 | 1.2-2.9 | |||||||

| 145 | 10 | 38.1-95.3 | 1.1-2.7 | |||||||

| 181 | 12.5 | 32.5-81.2 | 0.9-2.3 | |||||||

| ERC-30SA | 100 | 7 | 53.7-134.2 | 1.5-3.8 | 22/30 | 1200 | 850 | 1280 | 665 | 1 1/2″ |

| 116 | 8 | 50.8-127.1 | 1.4-3.6 | |||||||

| 145 | 10 | 45.2-113.0 | 1.3-3.2 | |||||||

| 181 | 12.5 | 39.5-88.3 | 1.1-2.8 | |||||||

| ERC-40SA | 100 | 7 | 74.9-187.1 | 2.1-5.3 | 30/40 | 1450 | 1000 | 1465 | 1110 | 1 1/2″ |

| 116 | 8 | 70.6-176.6 | 2.0-5.0 | |||||||

| 145 | 10 | 60.7-151.8 | 1.7-4.3 | |||||||

| 181 | 12.5 | 50.8-127.1 | 1.4-3.6 | |||||||

| ERC-50SA | 100 | 7 | 93.2-233.0 | 2.6-6.6 | 37/50 | 1450 | 1000 | 1465 | 1110 | 1 1/2″ |

| 116 | 8 | 87.6-218.9 | 2.5-6.2 | |||||||

| 145 | 10 | 80.5-201.3 | 2.3-5.7 | |||||||

| 181 | 12.5 | 65.0-162.4 | 1.8-4.6 | |||||||

| ERC-60SA | 100 | 7 | 113.0-282.5 | 3.2-8.0 | 45/60 | 1450 | 1000 | 1465 | 1750 | 1 1/2″ |

| 116 | 8 | 108.8-271.9 | 3.1-7.7 | |||||||

| 145 | 10 | 94.6-243.6 | 2.7-6.7 | |||||||

| 181 | 12.5 | 84.7-211.9 | 2.4-6.0 | |||||||

| ERC-75SA | 100 | 7 | 148.3-370.8 | 4.2-10.5 | 55/75 | 2100 | 1250 | 1700 | 1750 | 2″ |

| 116 | 8 | 138.4-346.0 | 3.9-9.8 | |||||||

| 145 | 10 | 122.9-307.2 | 3.5-8.7 | |||||||

| 181 | 12.5 | 103.1-257.8 | 2.92-7.3 | |||||||

| ERC-100SA | 100 | 7 | 192.1-480.2 | 5.4-13.6 | 75/100 | 2100 | 1250 | 1700 | 1840 | 2″ |

| 116 | 8 | 183.6-459.0 | 5.2-13.0 | |||||||

| 145 | 10 | 159.6-399.0 | 4.5-11.3 | |||||||

| 181 | 12.5 | 142.7-356.6 | 4.0-10.1 | |||||||

| ERC-120SA | 100 | 7 | 228.8-572.0 | 6.5-16.2 | 90/120 | 2170 | 1320 | 1750 | 2030 | 2″ |

| 116 | 8 | 217.5-543.8 | 6.2-15.4 | |||||||

| 145 | 10 | 186.4-466.1 | 5.3-13.2 | |||||||

| 181 | 12.5 | 158.2-395.5 | 4.5-11.2 | |||||||

| ERC-150SA | 100 | 7 | 293.8-734.45 | 8.3-20.8 | 110/150 | 2545 | 1500 | 1900 | 3100 | DN65 |

| 116 | 8 | 275.4-688.5 | 7.8-19.5 | |||||||

| 145 | 10 | 233.0-582.6 | 6.6-16.5 | |||||||

| 181 | 12.5 | 193.5-483.7 | 5.5-13.7 | |||||||

| ERC-175SA | 100 | 7 | 339.0-847.4 | 9.6-24 | 132/175 | 2545 | 1500 | 1900 | 3400 | DN65 |

| 116 | 8 | 324.9-812.1 | 9.2-23 | |||||||

| 148 | 10 | 282.5-706.2 | 8-20 | |||||||

| 181 | 12.5 | 218.9-547.3 | 6.2-15.5 | |||||||

| ERC-200SA | 100 | 7 | 392.6-981.6 | 11.1-27.8 | 160/200 | 2545 | 1500 | 1900 | 3400 | DN65 |

| 116 | 8 | 367.2-918.1 | 10.4-26 | |||||||

| 148 | 10 | 331.9-829.8 | 9.4-23.5 | |||||||

| 181 | 12.5 | 275.4-688.5 | 7.8-19.5 | |||||||

| ERC-250SA | 100 | 7 | 459.0-1147.6 | 13-32.5 | 185/250 | 2790 | 1550 | 2000 | 3780 | DN65 |

| 116 | 8 | 437.84-1094.6 | 12.4-31 | |||||||

| 148 | 10 | 367.2-918.1 | 10.4-26 | |||||||

| 181 | 12.5 | 305.1-762.7 | 8.6-21.6 | |||||||

| ERC-270SA | 100 | 7 | 487.3-1218.2 | 13.8-34.5 | 200/270 | 2850 | 1700 | 2000 | 4400 | DN80 |

| 116 | 8 | 466.1-1165.2 | 13.2-33 | |||||||

| 148 | 10 | 9395.5-88.7 | 11.2-28 | |||||||

| 181 | 12.5 | 331.9-829.8 | 9.4-23.5 | |||||||

| ERC-300SA | 100 | 7 | 536.7-1341.8 | 15.2-38 | 220/300 | 3150 | 2000 | 2120 | 4930 | DN100 |

| 116 | 8 | 515.5-1288.8 | 14.6-36.5 | |||||||

| 148 | 10 | 452.0-1129.9 | 12.8-32 | |||||||

| 181 | 12.5 | 381.4-953.4 | 10.8-27 | |||||||

| ERC-330SA | 100 | 7 | 1517.9-1518.3 | 17.2-43 | 250/330 | 3150 | 2000 | 2120 | 5450 | DN100 |

| 116 | 8 | 572.0-1430.1 | 16.2-40.5 | |||||||

| 148 | 10 | 515.5-1288.8 | 14.6-36.5 | |||||||

| 181 | 12.5 | 452.0-1129.9 | 12.8-32 | |||||||

| ERC-375SA | 100 | 7 | 727.4-1818.5 | 20.6-51.5 | 280/375 | 4000 | 2000 | 2100 | 6150 | DN125 |

| 116 | 8 | 706.2-1765.5 | 20-50 | |||||||

| 148 | 10 | 635.6-1589.0 | 18-45 | |||||||

| 181 | 12.5 | 522.6-1306.5 | 14.8-37 | |||||||

| ERC-420SA | 100 | 7 | 791.0-1977.4 | 22.4-56 | 315/420 | 4600 | 2300 | 2400 | 7500 | DN125 |

| 116 | 8 | 776.8-1942.1 | 22-55 | |||||||

| 148 | 10 | 692.1-1730.2 | 19.6-49 | |||||||

| 181 | 12.5 | 579.1-1447.7 | 16.4-41 | |||||||

| ERC-470SA | 100 | 7 | 903.9-2259.8 | 25.6-64 | 355/470 | 4600 | 2300 | 2400 | 8100 | DN150 |

| 116 | 8 | 875.7-2189.2 | 24.8-62 | |||||||

| 148 | 10 | 762.7-1906.7 | 21.6-54 | |||||||

| 181 | 12.5 | 649.7-1624.3 | 18.4-46 | |||||||

| ERC-550SA | 100 | 7 | 1031.0-2577.6 | 29.2-73 | 400/550 | 5000 | 2350 | 2400 | 8400 | DN150 |

| 116 | 8 | 988.7-2471.7 | 28-70 | |||||||

| 148 | 10 | 861.6-2153.9 | 24.4-61 | |||||||

| 181 | 12.5 | 734.4-1836.1 | 20.8-52 | |||||||

| ERC-600SA | 100 | 7 | 1144.0-2860.1 | 32.4-81 | 450/600 | 5500 | 2590 | 2800 | 9000 | DN150 |

| 116 | 8 | 1115.8-2789.5 | 31.6-79 | |||||||

| 148 | 10 | 988.7-2471.7 | 28-70 | |||||||

| 181 | 12.5 | 833.3-2083.3 | 23.6-59 | |||||||

| ERC-670SA | 100 | 7 | 1257.0-3142.6 | 35.6-89 | 500/670 | 5500 | 2590 | 2800 | 9500 | DN200 |

| 116 | 8 | 1228.8-3072.0 | 34.8-87 | |||||||

| 148 | 10 | 1087.6-2718.9 | 30.8-77 | |||||||

| 181 | 12.5 | 946.3-2365.8 | 26.8-67 | |||||||

| ERC-750SA | 100 | 7 | 1440.6-3601.6 | 40.8-102 | 560/750 | 6500 | 2700 | 3000 | 10000 | DN200 |

| 116 | 8 | 1384.2-3460.4 | 39.2-98 | |||||||

| 148 | 10 | 1228.8-3072.0 | 34.8-87 | |||||||

| 181 | 12.5 | 1087.6-2718.9 | 30.8-77 | |||||||

|

Motor Efficiency Class:Ultraefficient/IE3/IE2 as per your required |

||||||||||

You May Also Like

Belt / Direct Driven Compressor

7.5 – 250 kw @ 0.5 – 43 m3/min

Working Pressure: 7 – 16 bar

Learn More >>

2-Stage VSD Air compressor

18.5 – 355 kw @ 2.9 – 85.0 m3/min

Working Pressure: 5 – 12.5 bar

Learn More >>

Oil Free Screw Air Compressor

18.5 – 250 kw @ 2.3 – 43 m3/min

Working Pressure: 7 – 12.5 bar

Learn More >>