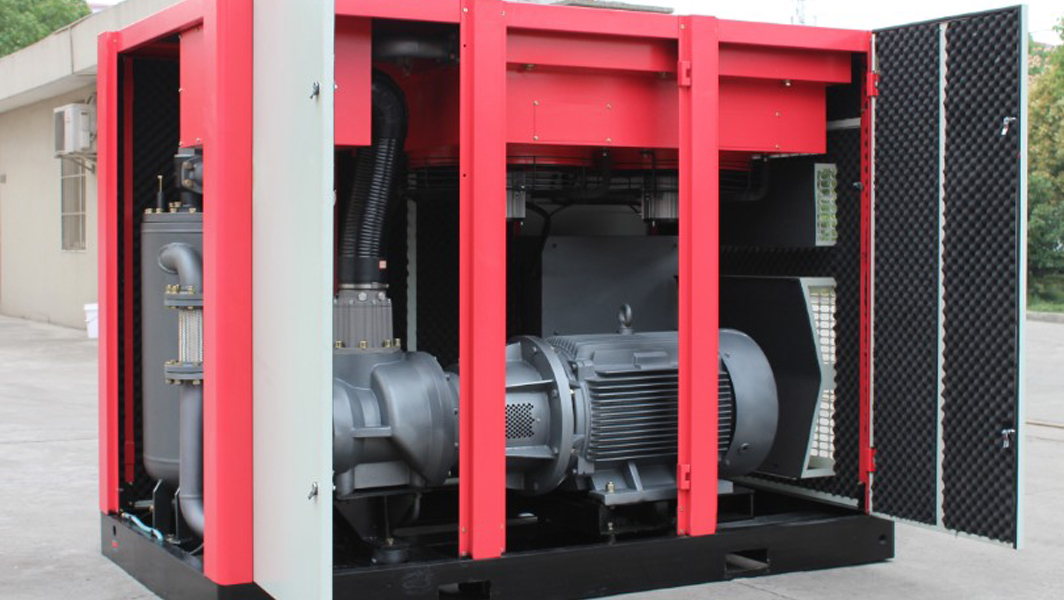

40HP 30kw 10Bar 4.3m3/min Fixed Speed Screw Air Compressor

Motor Power: 30 kw / 40 hp

Working Pressure: 10 bar / 145 psi

Air Delivery: 4.3 m3/min

to become an agent. Learn more about agency policy.

More competitive agent price by FCL!

Sometimes, the choice between belt-drive and direct-drive compressors is clear: if you need a machine of 50 HP or above, or are operating your compressor in a harsh environment, direct drive may be your best (or only) choice. A direct-drive air compressor offers significant advantages in terms of efficiency, reliability and longevity. However, if flexibility and up-front cost-savings are your priorities, a belt drive may be the right choice for your facility.

There are several factors to consider when choosing between a direct-drive vs. belt-drive compressor, including your usage patterns, available budget, energy costs, the usage environment and your maintenance capabilities.

- Air Usage: Continuous operation and high CFM demands favor direct-drive; for lower or variable demands, belt-drive might be better.

- Available Budget: Belt-drive offers lower initial costs, but direct-drive has lower total lifetime costs due to reduced maintenance and longer service life.

- Efficiency: Direct-drive compressors are more efficient, leading to lower energy costs.

- Usage Environment: Direct-drive compressors are better suited for harsh conditions, as belt drives can be sensitive to extreme temperatures and corrosive substances.

- Maintenance: Direct-drive requires less frequent maintenance, though when needed, it might be more costly and specialized.

Elang provides two different transmission methods for air compressors.

Elang Belt Driven Screw Air Compressor

Advantage:

Belt driven, which allows the speed of the rotor to be changed by different diameter pulleys.

1. The belt tension for each operating condition is optimized

2. By avoiding excessive start-up tension, greatly extending the belt working life

3. Always ensure the correct pulley connection

4. Replace the belt is very easy and fast, and do not need to adjust the original settings

5. The whole belt driven system safe and trouble-free operation.

Elang Direct Driven Screw Air Compressor

Advantage:

1. Large displacement: Displacement 10% higher than ordinary piston compressor.

2. Energy-saving: Compared with piston air compressor, this series of models for the new national standard two energy efficiency products, excellent energy saving.

3. Easy to operate: 24 hours unattended all day work, free load automatically start, full load automatically shut down.

4. Strong stability: Under long time working, displacement and pressure stable, no crash phenomenon, low failure rate.

Application:

Project

120HP Air Compressor Installation

Elang 30 sets 132kw air compressor in Ethiopia

Model: ERC-40SA

| Motor Power | Working Pressure | Air Delivery | Dimension(mm) | Weight(kg) | Output pipe Diameter |

|---|---|---|---|---|---|

| 30kw / 40hp | 7bar / 100psi | 187.1cfm / 5.3m3/min | 1450*900*1220 | 900 | 11/4″ |

| 30kw / 40hp | 8bar / 116psi | 176.6cfm / 5m3/min | 1450*900*1220 | 900 | 11/4″ |

| 30kw / 40hp | 10bar / 145psi | 151.8cfm / 4.3m3/min | 1450*900*1220 | 900 | 11/4″ |

| 30kw / 40hp | 13bar / 181psi | 127.1cfm / 3.6m3/min | 1450*900*1220 | 900 | 11/4″ |

You May Also Like

Belt / Direct Driven Compressor

7.5 – 250 kw @ 0.5 – 43 m3/min

Working Pressure: 7 – 16 bar

Learn More >>

Oil Free Screw Air Compressor

18.5 – 250 kw @ 2.3 – 43 m3/min

Working Pressure: 7 – 12.5 bar

Learn More >>

30 – 50 Bar Piston Compressor

9 – 22*3 kw @ 0.6 – 6.0 m3/min

Working Pressure: 30 – 50 bar

Learn More >>