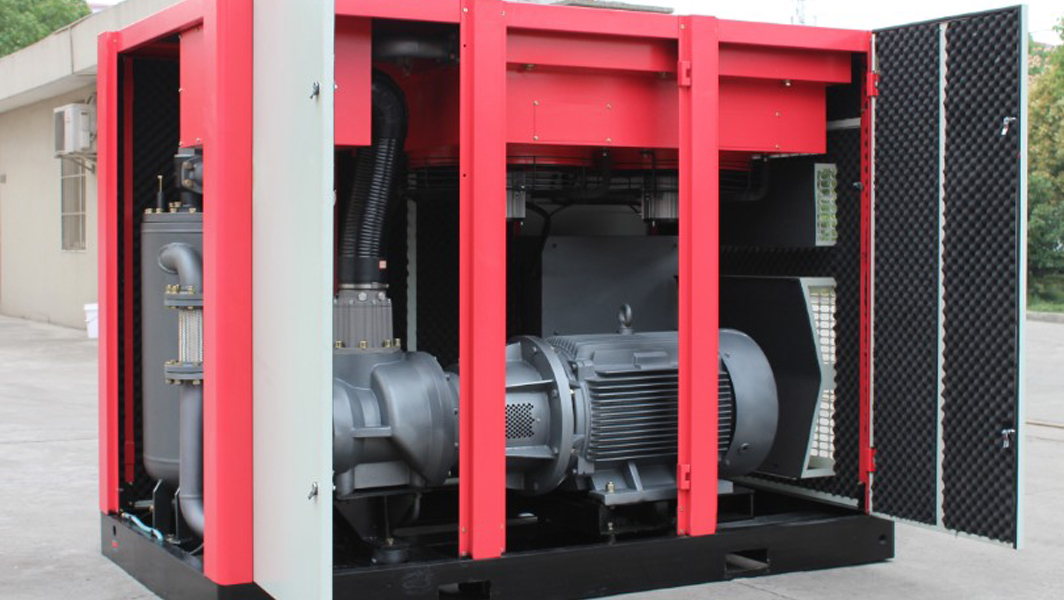

40HP 30kw 13Bar 3.6m3/min Fixed Speed Screw Air Compressor

Motor Power: 30 kw / 40 hp

Working Pressure: 13 bar / 181 psi

Air Delivery: 3.6 m3/min

to become an agent. Learn more about agency policy.

More competitive agent price by FCL!

When deciding between direct-drive and belt-drive air compressors, various factors must be taken into account, including usage patterns, budget constraints, energy costs, the operational environment, and maintenance capabilities. This choice is crucial for ensuring operational efficiency and cost-effectiveness in a wide range of industrial applications.

Direct-Drive Compressors: Efficiency and Durability for High Demand

Direct-drive air compressors are renowned for their high efficiency, reliability, and longevity, particularly suited for applications requiring high CFM (Cubic Feet per Minute) and continuous operation. These compressors directly connect the motor to the compressor, eliminating energy losses typically associated with belt-driven systems. This efficient transmission of power results in lower energy costs, making direct-drive compressors an excellent choice for operations where the compressor needs to run continuously or when air demand is high.

Moreover, direct-drive compressors are ideally suited for harsh operational environments or when the compressor’s horsepower exceeds 50 HP. The absence of belts means these compressors are less susceptible to environmental extremes, such as temperature fluctuations and exposure to corrosive chemicals, enhancing their durability and reducing maintenance needs in challenging conditions.

Elang provides two different transmission methods for air compressors.

Elang Belt Driven Screw Air Compressor

Advantage:

Belt driven, which allows the speed of the rotor to be changed by different diameter pulleys.

1. The belt tension for each operating condition is optimized

2. By avoiding excessive start-up tension, greatly extending the belt working life

3. Always ensure the correct pulley connection

4. Replace the belt is very easy and fast, and do not need to adjust the original settings

5. The whole belt driven system safe and trouble-free operation.

Elang Direct Driven Screw Air Compressor

Advantage:

1. Large displacement: Displacement 10% higher than ordinary piston compressor.

2. Energy-saving: Compared with piston air compressor, this series of models for the new national standard two energy efficiency products, excellent energy saving.

3. Easy to operate: 24 hours unattended all day work, free load automatically start, full load automatically shut down.

4. Strong stability: Under long time working, displacement and pressure stable, no crash phenomenon, low failure rate.

Application:

Project

120HP Air Compressor Installation

Elang 30 sets 132kw air compressor in Ethiopia

Model: ERC-40SA

| Motor Power | Working Pressure | Air Delivery | Dimension(mm) | Weight(kg) | Output pipe Diameter |

|---|---|---|---|---|---|

| 30kw / 40hp | 7bar / 100psi | 187.1cfm / 5.3m3/min | 1450*900*1220 | 900 | 11/4″ |

| 30kw / 40hp | 8bar / 116psi | 176.6cfm / 5m3/min | 1450*900*1220 | 900 | 11/4″ |

| 30kw / 40hp | 10bar / 145psi | 151.8cfm / 4.3m3/min | 1450*900*1220 | 900 | 11/4″ |

| 30kw / 40hp | 13bar / 181psi | 127.1cfm / 3.6m3/min | 1450*900*1220 | 900 | 11/4″ |

You May Also Like

Belt / Direct Driven Compressor

7.5 – 250 kw @ 0.5 – 43 m3/min

Working Pressure: 7 – 16 bar

Learn More >>

Oil Free Screw Air Compressor

18.5 – 250 kw @ 2.3 – 43 m3/min

Working Pressure: 7 – 12.5 bar

Learn More >>

30 – 50 Bar Piston Compressor

9 – 22*3 kw @ 0.6 – 6.0 m3/min

Working Pressure: 30 – 50 bar

Learn More >>