Under the background of the increasing awareness of global environmental protection, how to achieve high efficiency and energy saving of industrial production has become an important issue faced by the majority of enterprises.

As an indispensable part of industrial production, whether the design of air compressor station is efficient and energy-saving will directly affect the production cost and environmental protection of enterprises. Based on it, this paper explores the design of high efficiency and energy saving air compressor station from the following aspects for reference.

High Efficiency and Energy Saving Air Compressor Station Building Design Strategy

To brief, the air compressor station is a centralized supply of air equipment and facilities, widely used in indusrties production, construction engineering, medical equipment and other fields. In practice, it is found that the design of an efficient and energy-saving air compressor station needs to consider many factors, including equipment selection, layout optimization, control system and so on. Therefore, in the design of energy-saving air compressor station, the following effective strategies can be adopted:

Choose Efficient Equipment

energy efficiency label

First, efficient compressors can use energy more efficiently and reduce energy waste. Therefore, when choosing a compressor, pay attention to its energy efficiency level. For example, you can check the energy efficiency label of the compressor or consult the supplier to learn about its energy efficiency performance. It is also possible to consider the use of frequency conversion speed regulation technology to adjust the running speed of the compressor according to actual needs to further improve energy efficiency.

Second, different compressors are suitable for different working conditions, so the operation range of the compressor should be considered when selecting the compressor (such as the selected compressor can meet the actual needs of the air compressor station). This can communicate with the supplier to understand the working range and application scenarios of the compressor to ensure that the appropriate equipment is selected.

Third, the air compressor station room usually needs to be equipped with dryers, filters and other equipment to deal with the compressed air to remove moisture and impurities. Therefore, when selecting a compressor, it is also necessary to consider the matching of

Optimize Equipment Layout

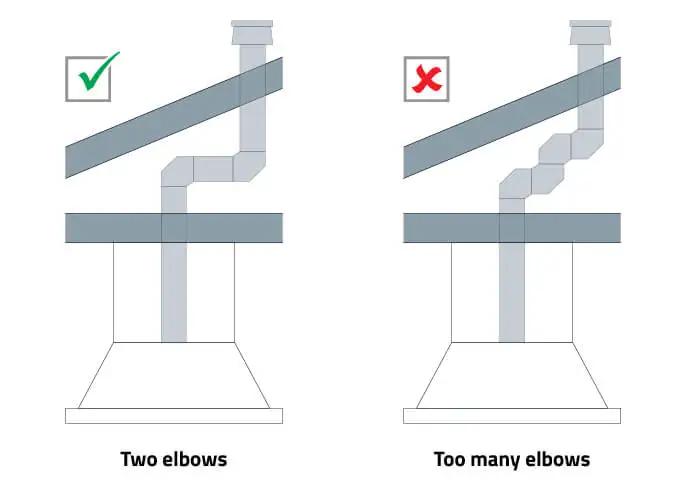

First, a reasonable pipeline layout can reduce the pressure loss of compressed air during transportation, thereby reducing energy consumption. Therefore, when designing an energy-efficient air compressor station, the direction and length of the pipeline should be reasonably planned according to the actual needs of the equipment and site conditions to reduce unnecessary pressure loss.

Third, reasonable equipment matching can ensure the collaborative work between the equipments and improve the operation efficiency of the entire air compressor station. Therefore, when designing an energy-efficient air compressor station, the working pressure, flow rate, power and other parameters of the equipment should be considered, and the combination of equipment with matching performance should be selected to achieve the best energy utilization effect.

Adopt Advanced Control System

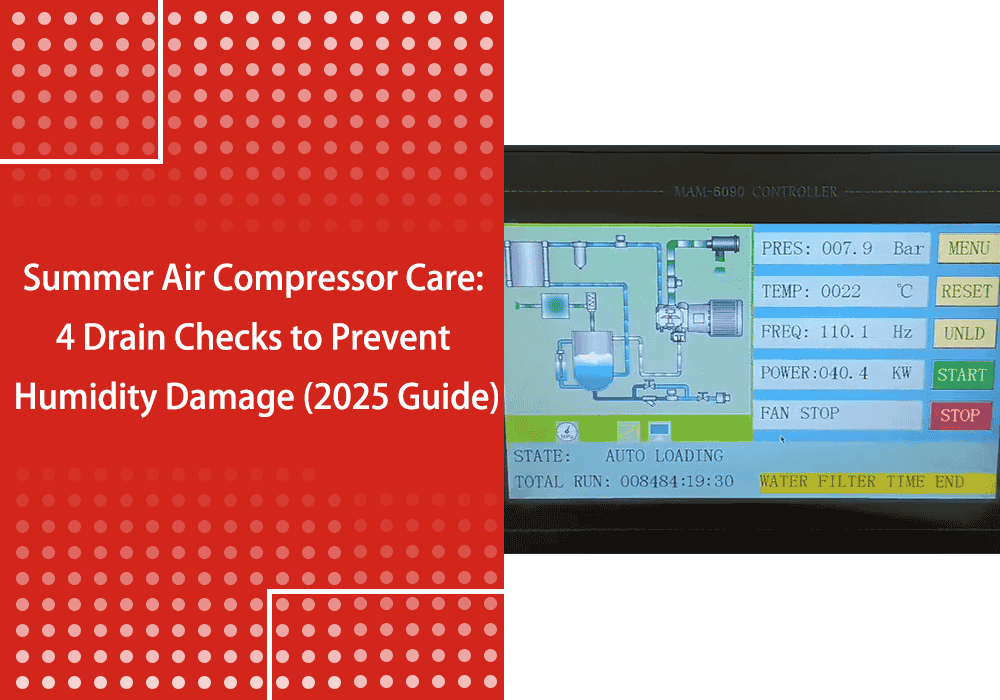

First, programmable logic controller (PLC) can be used to achieve automatic control of equipment. PLC is a computer control system specially designed for industrial environment, which can process various input signals and carry out corresponding output control according to preset programs. Through the use of PLC, it can realize the precise control of various equipment in the air compressor station, so as to improve the operating efficiency and stability of the equipment.

screw compressor PLC

Second, distributed control systems (DCS) can be used. DCS is a system integrating multiple controllers and monitoring equipment, which can realize the centralized management and control of the entire air compressor station. Through the use of DCS, the operation data of each equipment in the air compressor station can be monitored and recorded in real time, so as to discover and solve potential problems in time. In addition, DCS also has remote monitoring and control functions, which can be managed and maintained at any time along with the ground air compressor station.

Third, other advanced control systems, such as artificial intelligence (AI) and Internet of Things (IoT) technologies, can be considered. By applying these technologies to the control and management of the air compressor station, the intelligent level of the equipment can be further improved, and more accurate and efficient operation can be achieved. For example, by using AI algorithms to analyze and predict equipment operation data, signs of equipment failure can be detected in advance and corresponding measures can be taken for preventive maintenance. At the same time, by connecting the device to the Internet, remote monitoring and fault diagnosis can also be achieved, which greatly improves the maintenance efficiency and response speed.

Pay Attention to The Maintenance of Equipments

First, the layout of the equipment can be optimized to make it easy to clean and maintain. For example, equipment can be arranged in a relatively centralized area to facilitate cleaning and maintenance by operators. In addition, you can also consider the use of open equipment layout, so that the space between the equipment is more spacious, convenient for the operator to carry out maintenance and cleaning work.

Third, the equipment should be regularly maintained and maintained. This includes regularly checking the operating condition of the equipment, cleaning the surface and interior of the equipment, and replacing worn or aged parts. Through regular maintenance and maintenance, you can discover and solve potential problems of the equipment in time to ensure the normal operation and efficient performance of the equipment.

High Efficiency and Energy Saving Air Compressor Station Design Case

This case mainly takes small and medium-sized chemical plants as an example to design a high efficiency and energy saving air compressor station. In the current small and medium-sized chemical plants, air compressor station is an indispensable equipment. However, the traditional design of air compressor station in small and medium-sized chemical plants often has high energy consumption and low efficiency, which greatly reduces the economic benefits of enterprises. It can be seen that for small and medium-sized chemical plants, it is particularly important to design an energy-efficient air compressor station. So, how should small and medium-sized chemical plants design an energy-efficient air compressor station? In many years of practice, it has been found that the design of an energy-efficient air compressor station for small and medium-sized chemical plants needs to pay attention to the following key steps:

1. Site selection and station building layout design

When designing air compressor station buildings for small and medium-sized chemical plants, the location and layout of air compressor station buildings are two crucial links that need special attention, as follows:

First of all, the location of the air compressor station should be as close as possible to the load center, which can effectively reduce the distance of gas transmission and avoid the problem of gas quality reduction caused by long distance transmission. By arranging the air compressor station near the load center, the quality of the gas and the stability of the supply can be ensured, thus improving the production efficiency and product quality.

Finally, environmental protection and safety factors need to be considered in the location and layout of air compressor station buildings. Air compressor station buildings usually produce pollutants such as noise, vibration and exhaust gas, so they should be located away from residential areas and sensitive environments to reduce the impact on the surrounding environment and people. At the same time, it is also necessary to take corresponding measures, such as setting sound walls, installing shock absorption equipment and waste gas treatment devices, so as to reduce noise, vibration and emissions of waste gas, and protect the environment and personnel health.

In short, in the design of small and medium-sized chemical plant air compressor station, through reasonable location and layout, can ensure the function of the air compressor station and the stability of operation, improve production efficiency and product quality, while protecting the environment and personnel safety.

2. Equipment Selection

Air compressor station is an indispensable equipment in small and medium-sized chemical plants, its main function is to provide compressed air and instrument air for the factory. According to the different production needs, the air compressor station can further produce hydrogen. Therefore, choosing the right air compressor, dryer, filter and other equipment is crucial to ensure the smooth progress of production.

First of all, in the selection of air compressors, it is recommended to choose

Secondly, in the

Finally, in the selection of filters, we recommend the choice of self-cleaning air filters. The self-cleaning air filter adopts advanced self-cleaning technology, which can automatically remove dust and impurities on the filter screen during the filtration process, so as to ensure the stability of the filtration effect. This filter also has the advantages of long service life and low maintenance costs, which can save a lot of operating costs for the plant.

In short, when selecting the equipment of the air compressor station of small and medium-sized chemical plants, various factors should be considered according to the actual production needs of the factory, such as the operating efficiency of the equipment, energy consumption, noise, vibration, maintenance costs, etc., so as to select the most suitable equipment. Only in this way can we ensure the stable operation of the air compressor station and provide a strong guarantee for the production of the factory.

3. Pipeline Design

When designing pipelines for air compressor stations in small and medium-sized chemical plants, multiple factors need to be considered comprehensively, as follows:

Secondly, pipe diameter is also one of the key factors in pipe design. The choice of pipe diameter should be determined according to the flow and pressure requirements of the gas. The larger diameter of the pipe can provide a larger airflow channel, reduce the pressure loss of the gas, and improve the flow of the gas. However, excessive pipe diameters can lead to increased material costs and increased installation difficulty, so there is a trade-off between performance and economy.

Finally, the material of the pipe is also one of the important factors to consider. Different materials have different characteristics such as corrosion resistance, wear resistance and high temperature resistance, so it is necessary to choose the appropriate material according to the nature of the gas and the use environment. Common pipe materials include stainless steel, copper, aluminum, etc., each material has its scope of application and advantages and disadvantages, need to be selected according to the specific situation.

In addition to the above factors, pipeline design also needs to consider some other details. For example, the way pipes are connected and sealed has an important impact on the flow and quality of gas. Proper connection and reliable sealing measures can effectively prevent gas leakage and pollution to ensure that the quality of the gas meets the requirements.

In short, when designing the air compressor station of small and medium-sized chemical plants, through reasonable design and selection, it can effectively improve the transmission efficiency of gas, reduce energy consumption, and ensure the safe and stable operation of the production process.

4. Ventilation Design

When designing the ventilation system of the air compressor station building of small and medium-sized chemical plants, multiple factors need to be considered comprehensively, as follows:

Secondly, the air compressor station buildings of small and medium-sized chemical plants are small in scale, and most of their production analogies belong to class D and Class E. Therefore, in the plant layout, the layout design of the air compressor station should be carried out in strict accordance with the requirements of co-construction with other auxiliary projects, and the influence of natural ventilation and lighting on the air compressor station should be avoided.

Finally, in addition to the above factors, it is also necessary to refer to the relevant design specifications. For example, GB 50029-2014 “Compressed air station design code” is applicable to the design of new, rebuilt and expanded compressed air stations and compressed air pipelines of piston air compressors, diaphragm air compressors, screw air compressors and centrifugal air compressors with working pressure ≤42MPa driven by electricity. In short, good ventilation design can ensure the normal operation and safety of the air compressor station.

5. Operation Management

The operation management of air compressor station is the key link to ensure its safe, stable and efficient operation. The following are some suggestions:

(1) Equipment use and maintenance management: to ensure the normal use of air compressors and related equipment, regular maintenance, timely replacement of worn or damaged parts. For major repairs that require longer downtime, detailed plans should be made and strictly implemented.

(2) digital operation and maintenance management: Combined with modern Internet and digital technology, the air compressor and its surrounding auxiliary equipment are unified digital operation and maintenance management. This can not only fully guarantee the safety of air compressor equipment, but also reduce the energy consumption of gas stations, reduce maintenance costs, and improve management efficiency.

(3) Intelligent energy-saving control: The use of modern technical means, such as AI control, intelligent frequency conversion and power quality monitoring, centralized regulation and management of equipment. These technologies can realize self-learning of the energy supply system and provide the best fit for highly intelligent centralized control the operating parameters.

(4) Multidimensional energy consumption monitoring and energy management system: to realize the data, management dynamics and data visualization of energy consumption in the whole plant area. The system can also predict and evaluate the energy-saving measures, and provide decision-making support for the energy-saving countermeasures of enterprise facilities.

(5) Customized energy saving schemes: according to the actual working conditions and energy consumption of the chemical plant, a dedicated energy saving scheme is developed to continuously optimize energy efficiency and the operation of the entire air pressure system.

(6) Safety management: Ensure the safe operation of the air compressor station and prevent safety accidents caused by equipment failure or other reasons.

In short, the operation and management of air compressor station buildings in small and medium-sized chemical plants not only needs to pay attention to the normal operation and maintenance of equipment, but also needs to combine modern technology and management means to achieve efficient, safe and energy-saving operation of air compressor stations.

To sum up, the design of air compressor station buildings in small and medium-sized chemical plants should not only consider the site selection and station layout design, but also be fully examined.

Conclusion

As an indispensable part of industrial production, whether the design of air compressor station is efficient and energy-saving will directly affect the production cost and environmental protection of enterprises. Therefore, exploring the design of efficient and energy-saving air compressor station will have extremely important guiding significance for promoting the good development of the majority of enterprises and realizing efficient and energy-saving production. At the same time, we believe that with the efforts of the majority of enterprises, the future design of air compressor station will be more efficient, energy saving and environmental protection, so as to create greater benefits for the majority of enterprises.

Our Case

Related Reading

An air compressor room that meets the standards needs to include multiple factors such as fire prevention, environment, and layout.

The placement and design of a compressed air system is a task that requires careful consideration, taking into account the design of the compressor room, its location, infrastructure, ventilation, and potential future expansions.

Extensive Reading

Should I choose one large air compressor or multiple smaller ones? Many customers have met this problem when selecting an air compressor solution.