Rotary Screw Vacuum Pumps With VSD

Motor Power: 11 – 110 kw

Flow Rate: 735 – 6390 m3/hr

Inlet Size(PN1.0): DN80 – DN250

to become an agent. Learn more about agency policy.

More competitive agent price by FCL!

Elang continues to pay attention to the latest achievements of vacuum technology in the world and take the lead in applying frequency conversion technology to vacuum pumps, successfully solving the problems of starting and changing working conditions. Innovative applications in different vacuum fields create value for users. Vacuum solutions bring value for users.

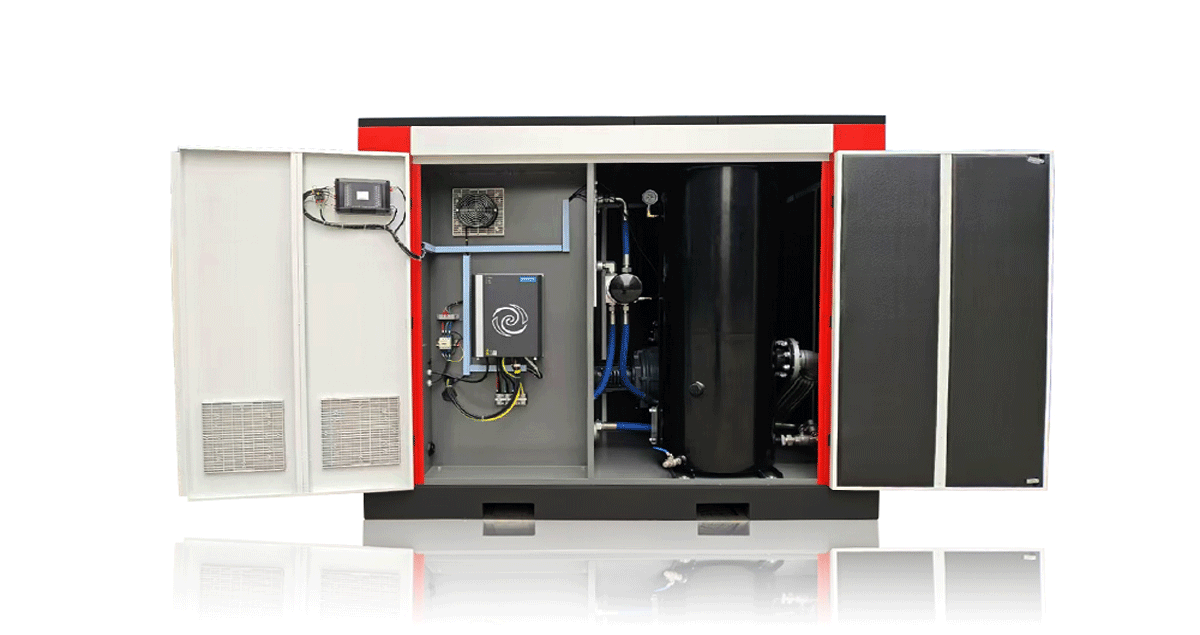

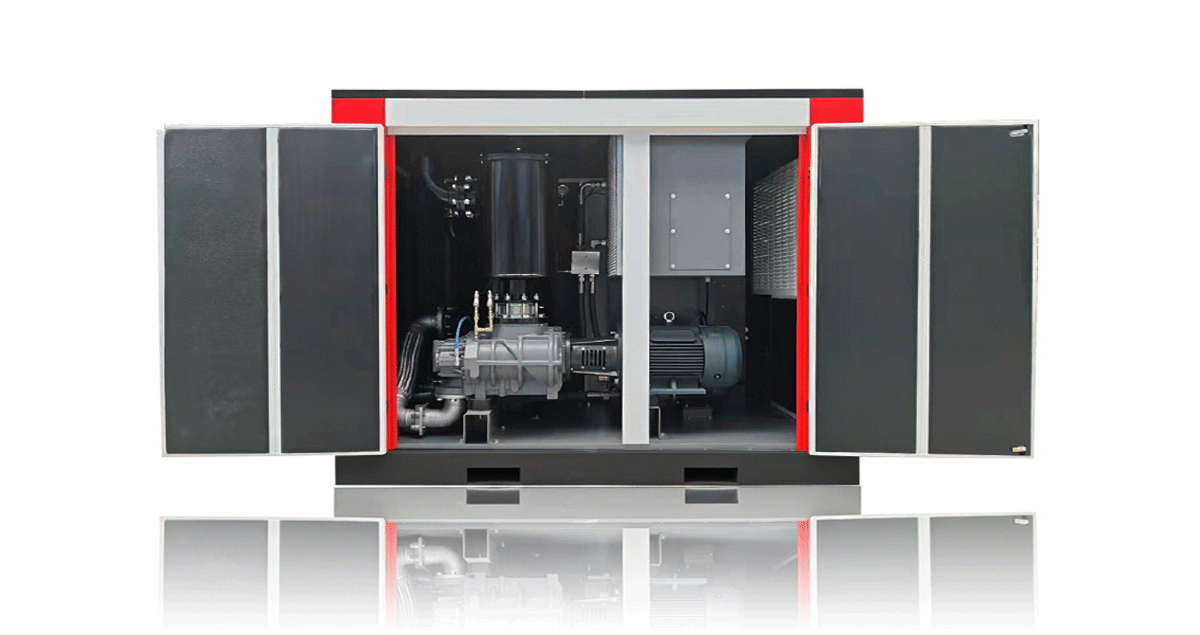

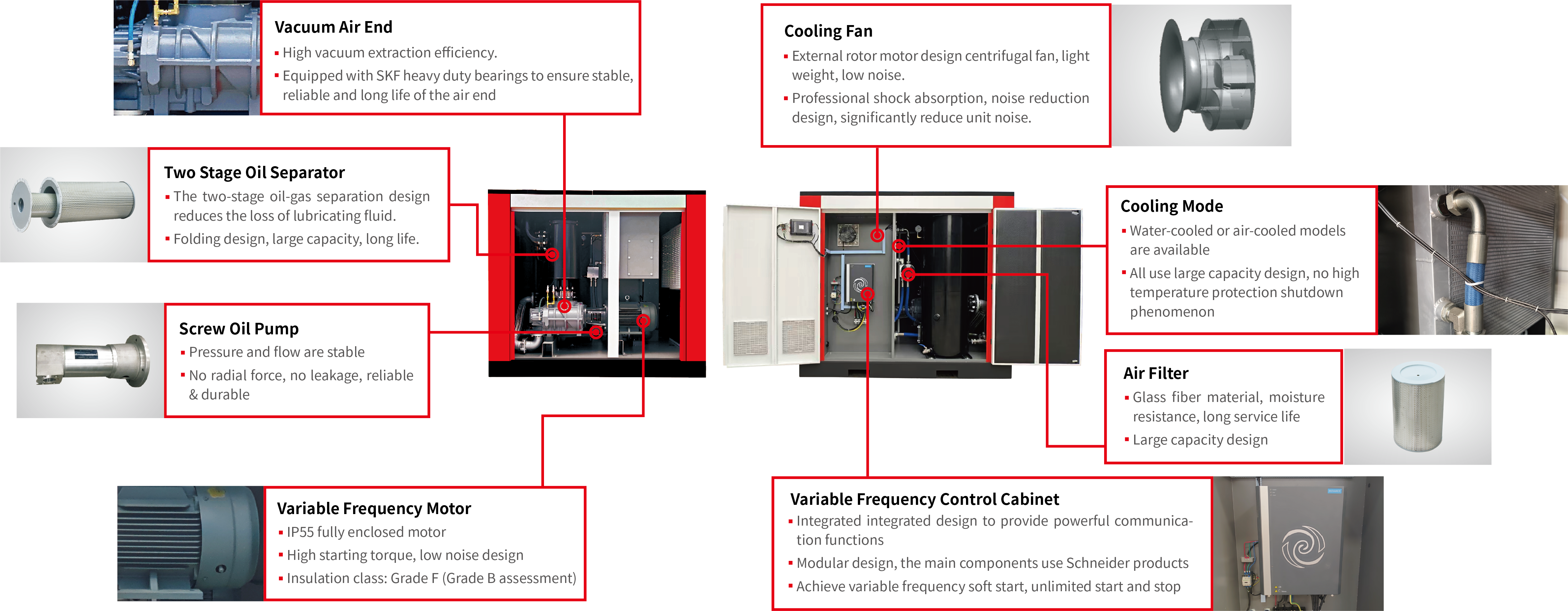

VSD Oil Injection Screw Vacuum Pump Components Analysis

Advantages

- High Air Quality Standards

- Efficiently processes inhaled air, ensuring no contamination from liquids or solid particles, thereby maintaining a clean working environment.

- Corrosion Resistance

- Sensitive to corrosive gases, making it suitable for industrial scenarios requiring high-precision protection.

- Key Component of Vacuum Systems

- As an integral part of vacuum application solutions, it directly impacts the overall performance and efficiency of the system.

- High Stability and Reliability

- Ensures stable operation and high reliability, meeting the demands of industrial processes for long-term usage.

- Preprocessing Capability

- Offers robust preprocessing functionality, supporting the overall vacuum system and optimizing operational performance.

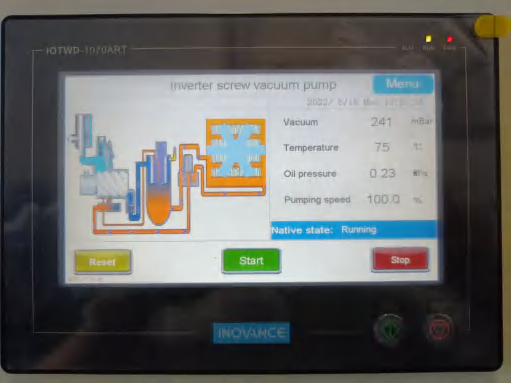

Controller

Vacuum solutions for every application

From Electronics, vacuum casting, printing, material handling, hospital, aerospace, blister, semiconductor packaging, canning, LED, paper holder, paper making, foam and packaging, to almost all general manufacturing, utility vacuum is used across industries in multiple applications.

As the leading innovator in the industrial vacuum market, we have continued focus on energy efficiency that translates into savings for our customers. Whatever the application, we provide the apt vacuum solution.

| Oil injection screw vacuum pump technical parameters | |||||||||

| Model | Motor Power | Flow Rate | Ultimate Vacuum | Inlet Size | Outlet Size | Dimension | Weight | ||

| Kw | M3/hr | mbar | PN1.0 | PN1.0 | L | W | H | Kg | |

| EOV750 | 11 | 735 | 0.68 | DN80 | DN80 | 1600 | 1080 | 1580 | 780 |

| EOV900 | 15 | 885 | 0.68 | DN80 | DN80 | 1600 | 1080 | 1580 | 950 |

| EOV1300 | 22 | 1293 | 0.68 | DN100 | DN100 | 2000 | 1250 | 1700 | 1350 |

| EOV1600 | 30 | 1585 | 0.68 | DN100 | DN100 | 2000 | 1250 | 1700 | 1500 |

| EOV2000 | 37 | 1950 | 0.68 | DN100 | DN100 | 2000 | 1250 | 1700 | 1650 |

| EOV2500 | 45 | 2480 | 0.68 | DN125 | DN150 | 2450 | 1650 | 2000 | 2450 |

| EOV3600 | 55 | 3632 | 0.68 | DN150 | DN200 | 2926 | 1820 | 960 | 3650 |

| EOV4500 | 75 | 4492 | 0.68 | DN150 | DN200 | 2926 | 1820 | 960 | 4200 |

| EOV5500 | 90 | 5562 | 0.68 | DN250 | DN200 | 2926 | 1820 | 960 | 4500 |

| EOV6500 | 110 | 6390 | 0.68 | DN250 | DN200 | 3500 | 1900 | 2200 | 4900 |

You May Also Like

Belt / Direct Driven Compressor

7.5 – 250 kw @ 0.5 – 43 m3/min

Working Pressure: 7 – 16 bar

Learn More >>

Oil Free Screw Air Compressor

18.5 – 250 kw @ 2.3 – 43 m3/min

Working Pressure: 7 – 12.5 bar

Learn More >>

30 – 50 Bar Piston Compressor

9 – 22*3 kw @ 0.6 – 6.0 m3/min

Working Pressure: 30 – 50 bar

Learn More >>