12. What is The Working Principle of The Oil-gas Separation?

The lubricating oil contained in the exhaust gas is the consumption of oil in oil injection screw air compressors.To reduce the oil consumption, oil and gas separators typically employ a combination of mechanical and affinity coalescing methods, known as two-stage separation.

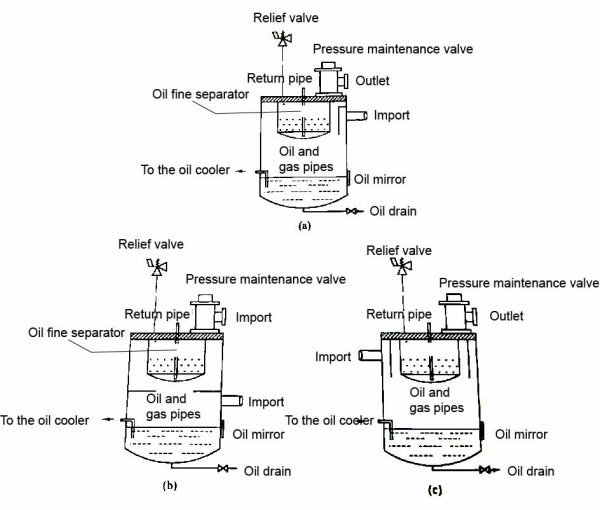

Generally, there are three different structural types of oil-gas separators:

(a) Method 1; (b) Method 2; (c) Method 3

(a) Method 1 is the form that was commonly used in early oil-gas separators. After the oil and gas mixture enters the oil-gas separator from the air compressor, it first impacts the baffle wall surface set in the separator, and undergoes a primary separation using the mechanical collision method. And then the oil-gas mixture enters the oil-fine separator at a lower speed for secondary separation.

Both structural styles shown in (b) Method 2 and (c) Method 3 combine collision and cyclonic separation for secondary separation.

In (b) Method 2, the oil-gas mixture enters tangentially from the bottom of the oil-fine separator, flows through the preset cyclone channel, and uses the centrifugal force formed by the rotation to perform a primary separation. Compared with the simple collision method, the primary separation effect of this structural style has been improved, but still has some disadvantages:

(1) Firstly, the addition of the cyclonic channel increases the height of the oil-gas separator.

(2) Secondly, the direct passage of the oil and gas mixture over the oil surface reduces the separation efficiency.

(3) Thirdly, since the cyclonic channel is generally welded to the lower part of the oil-gas separator, it is very difficult to clean the bottom of the oil-gas separator.

The structural form depicted in (c) Method 3 involves placing a cylinder between the oil finer separator and the oil and gas separator wall, with the space between the separator wall and the cylinder serving as the cyclonic channel. The oil and gas mixture enters tangentially from the upper part of the separator, and is separated once by using the centrifugal force formed by the rotation. This method offers effective separation while avoiding the disadvantages in the structure of (b) Method 2, it is more and more widely used.

The lubricating oil separated by the oil finer separator gathers at the bottom of the separator and needs to be drawn out through the return oil pipe and discharged to the intake port of the compressor or to the inter-tooth volume at a lower pressure.