06. What are The Types of Intake Valves for Screw Compressors?

- Piston Intake Valve:

When the air compressor starts, stops, or operates without a load, the operation of the air compressor on the empty/full vehicle is controlled by the up and down movement of a piston inside the intake valve. The venting solenoid valve supplies air to the piston through the intake port, causing the piston to close upward. When the air compressor operates at full load, the venting solenoid valve is powered off to stop venting, and the piston chamber exhausts through the exhaust port. Due to the pressure difference, the intake valve piston descends, fully opening the intake valve, and the air compressor operates at full load. When the pressure reaches the set upper limit, the venting solenoid valve is de-energized, initiating venting. It also pushes up the intake valve piston, causing the intake valve to close. At this point, the air compressor enters an unloaded state.

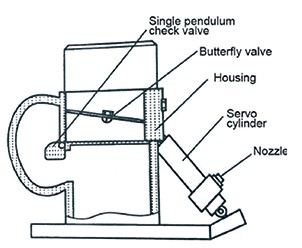

The structure of the piston-type intake valve consists of the intake port, valve cap, piston, base, and venting solenoid valve. The structural diagram is as follows:

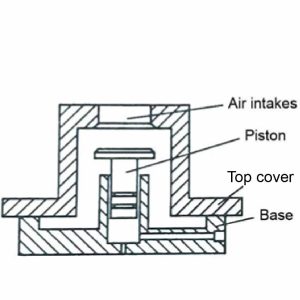

- Butterfly Control Valve:When the air compressor is started, the intake valve’s valve plate remains closed to ensure a load-free startup. As the electric motor operates under heavy load, the three-phase solenoid valve is energized and opened. The gas from this process enters the servo cylinder of the intake valve, pushing the valve rod of the servo cylinder, which in turn drives the intake butterfly valve to fully open, initiating heavy-load operation.

Inside the butterfly intake control valve, there is a single-pendulum check valve with its own counterweight and fluorine rubber sealing ring. During startup, the compressor’s main unit suctions air, and due to the pressure difference, the check valve quickly opens. When the compressor stops, the pressure difference is lost, and the check valve is promptly and tightly closed, ensuring there is no phenomenon of oil discharge during shutdown.

The opening and closing of the butterfly valve are controlled by the controlled cylinder. Based on the received pressure signal and in conjunction with the proportional valve, the length of the piston rod of the controlled cylinder can be extended or retracted, causing the butterfly valve to open or close. This, in turn, adjusts the air intake of the compressor.

The structure of the butterfly intake control valve consists of the valve body, single-pendulum check valve, butterfly valve, and servo cylinder. The structural diagram is as follows: